Factory Outlets Curve Roof Roll Forming Machine - Factory Price For Roll Shutter Door Roll Forming Machine In – Haixing Industrial Detail:

We’re going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Factory Price For Roll Shutter Door Roll Forming Machine In, Objects won certifications using the regional and international primary authorities. For far additional detailed data, you should get hold of us!

We’re going to dedicate ourselves to offering our esteemed shoppers with the most enthusiastically considerate solutions for Roller Shutter Door Machine, Rolling Shutter Slats Roll Forming Machine, Used Roller Shutter Roll Forming Machine, High output volume, top quality, timely delivery and your satisfaction are guaranteed. We welcome all inquiries and comments. We also present agency service—that act as the agent in china for our customers. If you are interested in any of our products and solutions or have an OEM order to fulfill, make sure you feel free to contact us now. Working with us will save you money and time.

Machine parameters

|

Roller shutter door roll forming machine |

||

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgs

Manual decoiler |

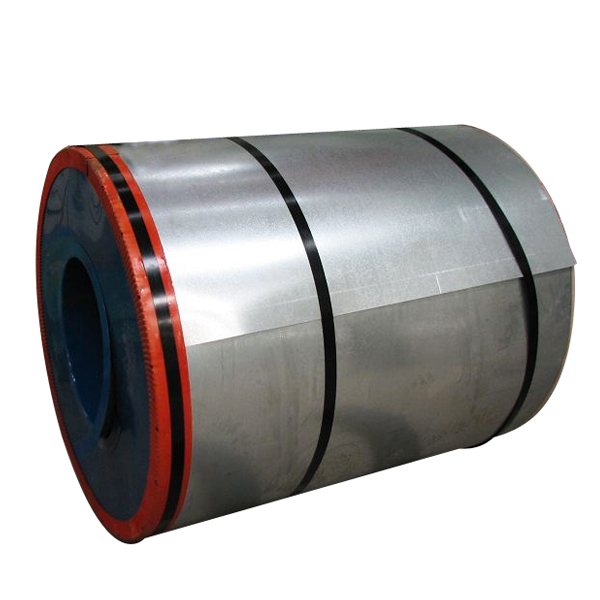

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.

Other elements are from famous suppliers of China. |

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

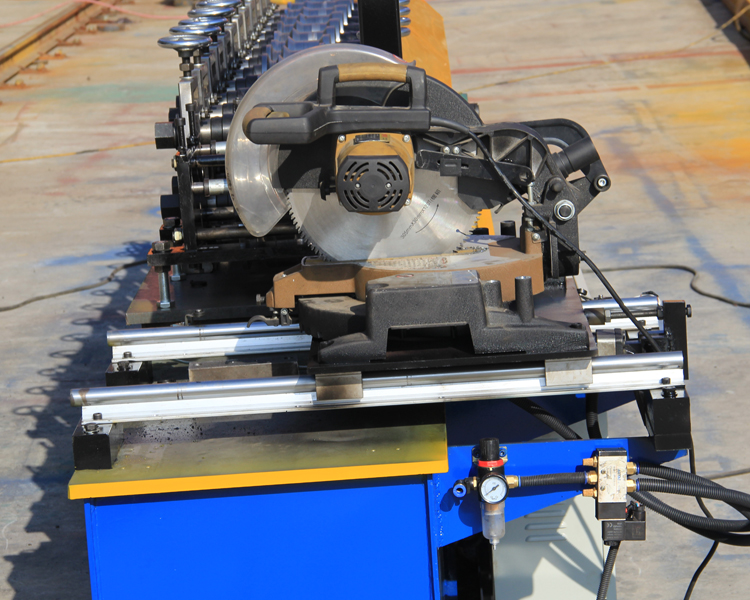

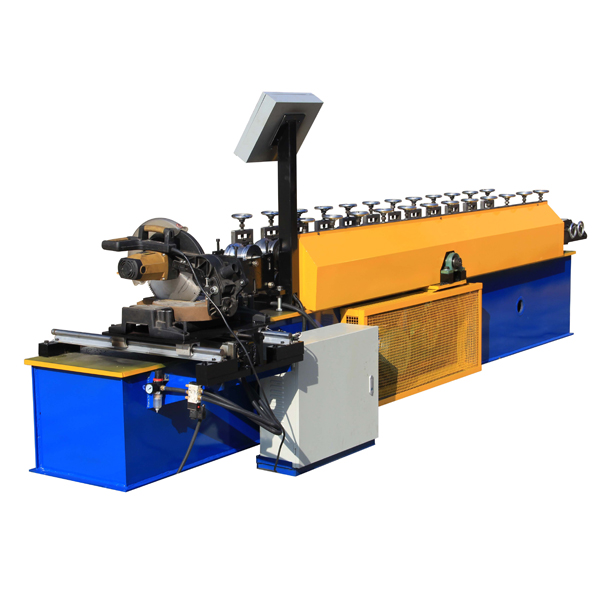

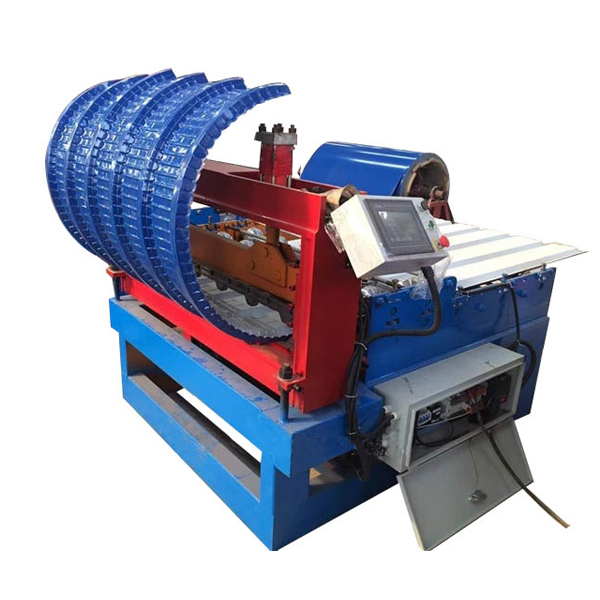

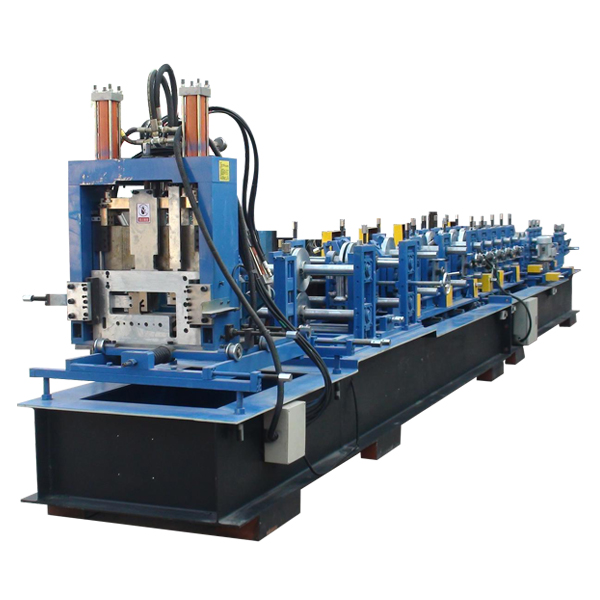

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

Product detail pictures:

Related Product Guide:

Royal Caribbean Symphony of the Seas suites in photos | Floor Deck Macking Machine

Specifications for Commercial Skylights | Roof Sheet Curving Machine

Factory Outlets Curve Roof Roll Forming Machine - Factory Price For Roll Shutter Door Roll Forming Machine In – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Chinese Professional Manual Tile Press Machine ...

-

OEM Supply Ordinary Roof Tile Machine - Roof P...

-

Factory source Steel Plate Hydraulic Bending Ma...

-

Reliable Supplier Roof Tile Machine - Metal Sh...

-

factory low price Roof Tile Sheet Rolling Formi...

-

Wholesale Price Double Layle Metal Tile Making ...