We thinks what clients think, the urgency of urgency to act inside the interests of a customer position of basic principle, allowing for much better high quality, reduce processing costs, charges are additional reasonable, won the new and previous customers the support and affirmation for Factory made hot-sale Pacific Uncoiler Straightening Machine Flatbed Leveling Machine Stamping Automatic Straightener Coil Feeder Production Line, Together with the everlasting target of “continuous top quality improvement, customer satisfaction”, we have been sure that our products high quality is stable and trustworthy and our solutions are best-selling at your home and overseas.

We thinks what clients think, the urgency of urgency to act inside the interests of a customer position of basic principle, allowing for much better high quality, reduce processing costs, charges are additional reasonable, won the new and previous customers the support and affirmation for , We focus on providing service for our clients as a key element in strengthening our long-term relationships. Our continual availability of high grade solutions in combination with our excellent pre-sale and after-sales service ensures strong competitiveness in an increasingly globalized market. We have been willing to cooperate with business friends from at home and abroad and create a great future together.

The setting of the leveling machine depends mainly on the thickness, material and requirements of the strip being tested.

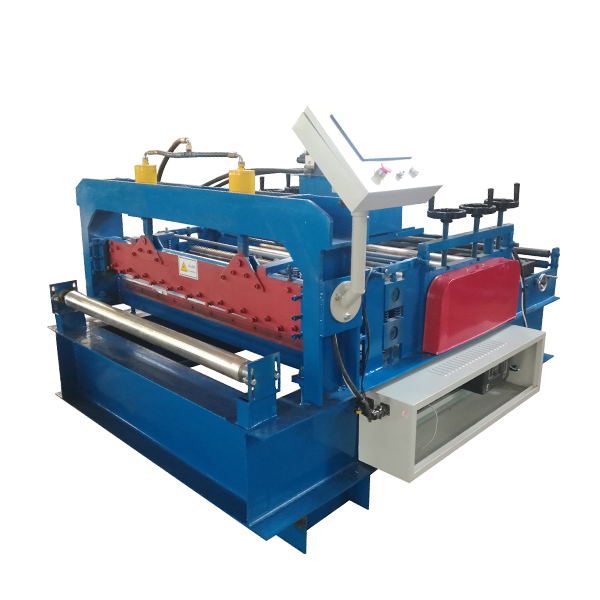

Sheet Coil Leveling Machine parameters:

| 1 | Suitable to process | PPGI, galvanized sheet |

| 2 | Thickness of raw material | Slitting: Max 0.8mm

Cutting: Max 2.0mm |

| 3 | Roller station | Up: 5 rollers

Down: 6 rollers |

| 4 | Voltage | 380V, 50HZ, 3Phase |

| 5 | Main Frame | 350 H beams |

| 6 | Side panel thickness | 40mm |

| 7 | Diameter of shaft | ¢90mm |

| 8 | Chain size | 1 inch |

| 9 | Motor power | 3 Kw (Siemens) |

| 10 | PLC | Delta/Siemens |

| 11 | Transmission | Gear transmission |

| 12 | Machine size | 2200*2000*2000mm |

| 13 | Machine weight | About 2 tons |

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

2019 Good Quality Roofing Tiles Press Forming M...

-

Reliable Supplier China Hydraulic Pressure Colo...

-

Original Factory High quality high speed iso ce...

-

Short Lead Time for Omega Profile Roll Forming ...

-

Wholesale Price China China Profile Extrusion M...

-

Manufactur standard Low Rolling Up Cold Steel I...