We not only will try our greatest to supply excellent solutions to just about every consumer, but also are ready to receive any suggestion offered by our consumers for Factory Free sample Hydraulic Trapezoidal Used Roofing Sheets Making Machine, We are going to continually strive to boost our company and offer the top high quality goods with aggressive costs. Any inquiry or comment is extremely appreciated. Be sure to make contact with us freely.

We not only will try our greatest to supply excellent solutions to just about every consumer, but also are ready to receive any suggestion offered by our consumers for Aluminium Roofing Sheet Making Machine, Metal Roof Tile Making Machine, Roof Tiles Roll Forming Machine, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our items, remember to do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

Our Service Advantage

1. Professional: rich experience in product and export process!

2. Low price: Save your money from every part!

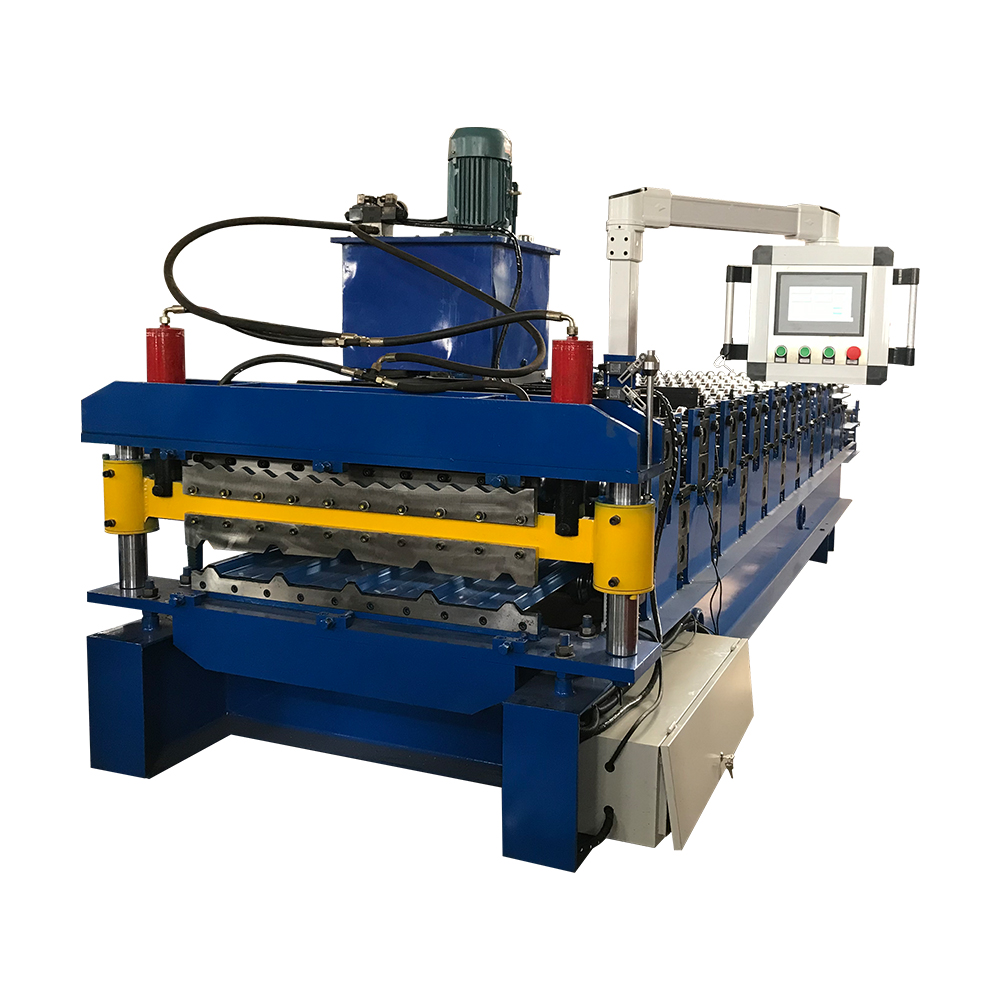

Parameters of double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Machine photos

Components of double roof tile machine

| No. | Name | Unit | Quantity |

| 1 | Manual decoiler | Set | 1 |

| 2 | Main forming machine | Set | 1 |

| 3 | PLC control system | Set | 1 |

| 4 | Hydraulic pump station | Set | 1 |

| 5 | Post cut | Set | 1 |

| 6 | Electric motor | Set | 1 |

| 7 | Output table | Set | 1 |

Machine package and shipment details

Standard export packing: 1*40 GP container,main machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, electrics devices be packed with wooden box.

Why choose us ?

Professional:

With 10 years’ professional manufacturing experience in roll forming machinery;

Professional production line,well -trained workers,strict QC standard.