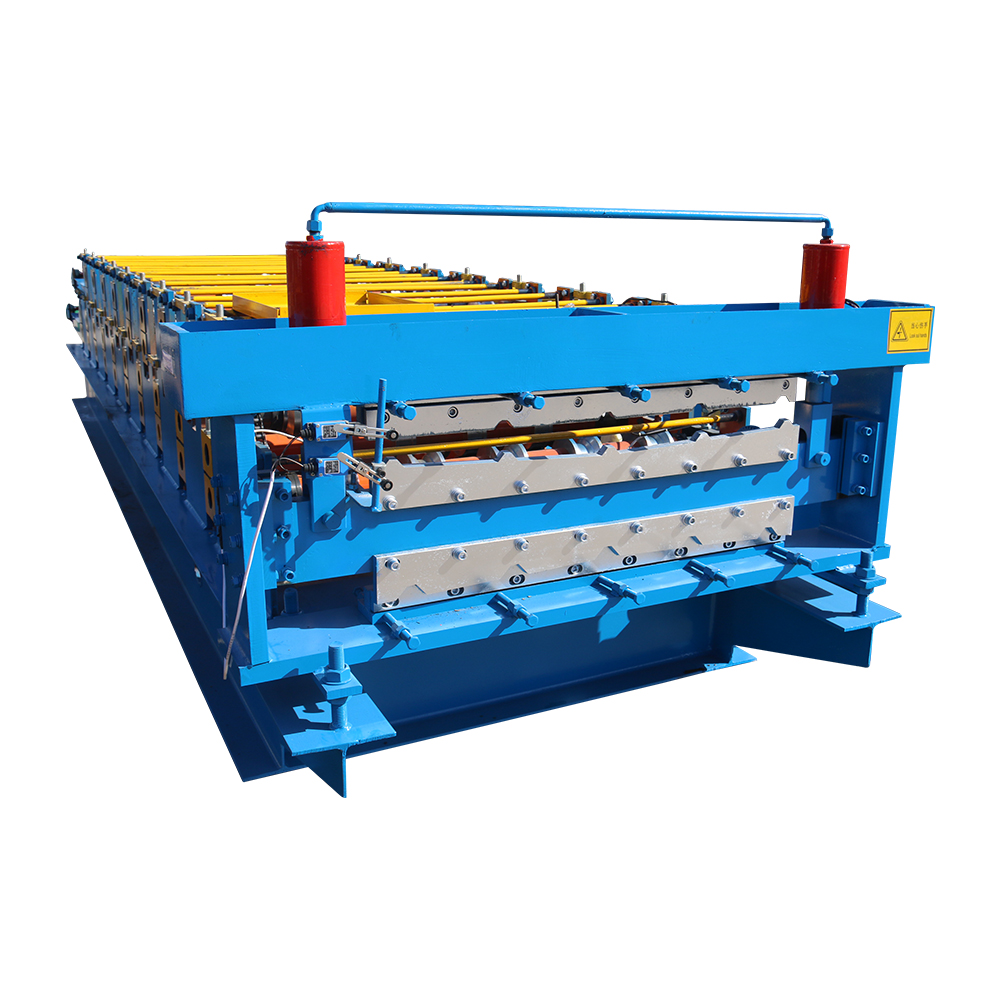

Factory directly Stud And Truss Ceiling Roofing Machine - Trapezoidal Sheet Roll Forming Machine – Haixing Industrial Detail:

|

Trapezoidal Sheet Roll Forming Machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The application of metal roof sheets for house and villas:

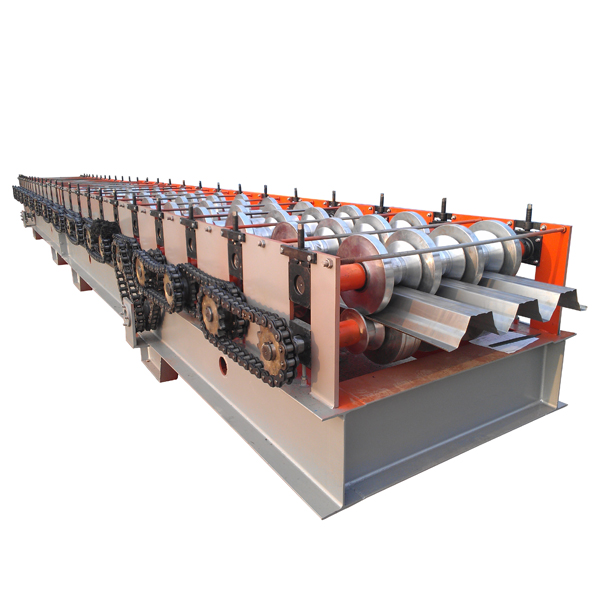

It can produce several of steel roof and wall panel, the products are widely used as the roof and wall of factory, warehouse, garage, gymnasium, exhibition center, cinema, theatre, etc.

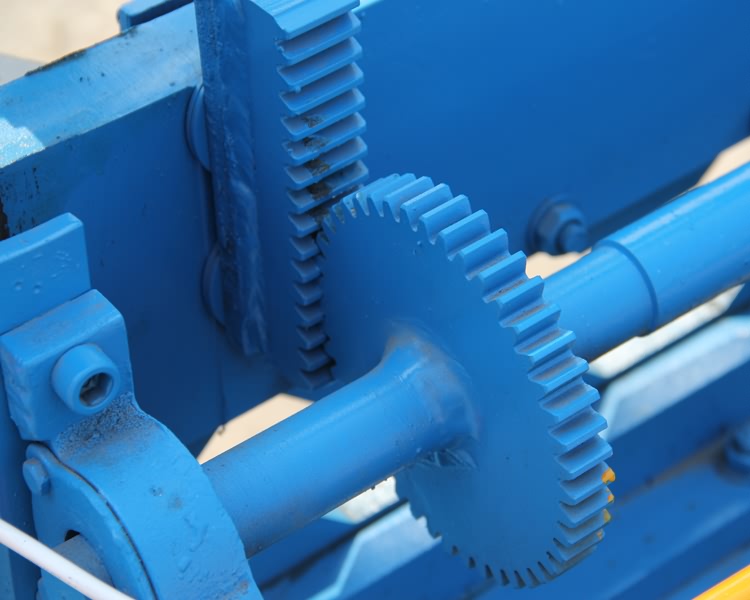

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Product detail pictures:

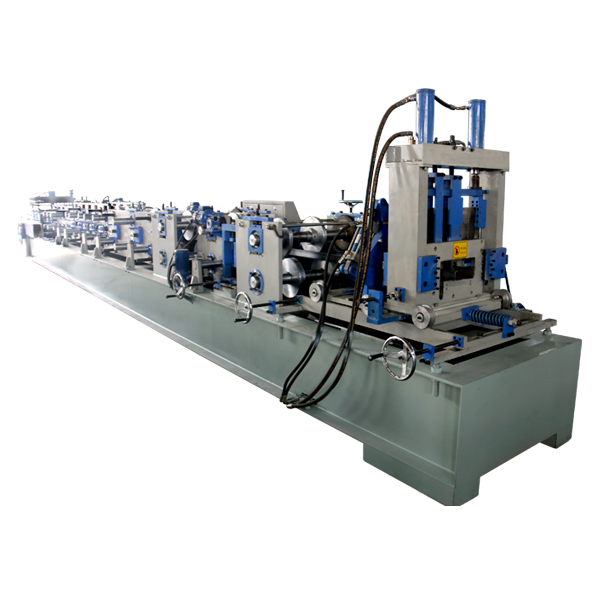

Related Product Guide:

A city made of cardboard in an art gallery | Ibr Roof Sheet Making Machine

The Incredible True Story of the Henrietta C. | Floor Deck Macking Machine

Factory directly Stud And Truss Ceiling Roofing Machine - Trapezoidal Sheet Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Cheapest Factory Steel Gutters And Downspount F...

-

Factory selling Steel Profile Shutter Door Fram...

-

Factory selling Ceiling Grid Machine - Steel F...

-

Professional China Highway Guardrail Plate Maki...

-

OEM/ODM Factory Automatic Metal Roofing Sheet B...

-

Bottom price Angel Bending Machine - C Purlin ...