The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Factory directly Galvanized C Z/cz Purlin Cold Roll Forming Machine, We are going to do our best to fulfill your specifications and are sincerely searching forward to building mutual valuable organization romantic relationship along with you!

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for Cz Purlin Cold Roll Forming Machine, Galvanized C Z/cz Purlin Cold Roll Forming Machine, Roll Forming Machine, Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. now we have insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

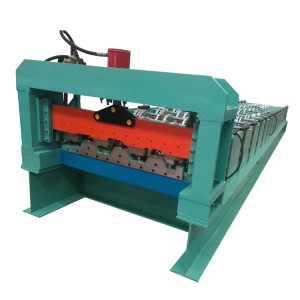

C purlin channel roll forming machine process:

The strip is fed from the tail of the equipment and pressed through various press rolls to form a C-shaped steel to be sent out from the head.

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m).

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery)