Factory Cheap Hot Sandwich Panel Manufacturing Line - OEM/ODM China Steel Roof Truss Making Machinery Metal Roll Forming U C Z Purlin Machines – Haixing Industrial Detail:

We’ve got a highly efficient group to deal with inquiries from shoppers. Our purpose is “100% client fulfillment by our product high-quality, price tag & our staff service” and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of OEM/ODM China Steel Roof Truss Making Machinery Metal Roll Forming U C Z Purlin Machines, We are sincerely looking forward to creating superior cooperative relationships with clients from in the home and overseas for creating a vibrant foreseeable future together.

We’ve got a highly efficient group to deal with inquiries from shoppers. Our purpose is “100% client fulfillment by our product high-quality, price tag & our staff service” and enjoy a superb reputation amongst clientele. With quite a few factories, we will provide a wide variety of Making Machinery, Purlin Machine, U C Z Purlin Machines, Our monthly output is more than 5000pcs. We have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We are and will be always trying our best to serve you.

Automatic CZ interchange purlin machine process flow:

Manual decoiler– punching hole– roll forming machine– molding press– PLC control box– hydraulic system– post cut– output table.

|

Purlin roll forming machine |

||

| 1 | Suitable to process | Steel plate |

| 2 | Rollers | 18 rows(Before and after the leveling and contains no lead to send passes) |

| 3 | Dimensions | 11*1.3*1.5m |

| 4 | Power | 11.5kw+7.5kw |

| 5 | Thickness of the plate | 1-3mm |

| 6 | Productivity | 8-10m/min |

| 7 | Middle plate thickness | 20mm |

| 8 | Driving ways | 2.6-inch China wheels and link chain |

| 9 | Diameter and material of the forming axis | 80mm |

| 10 | Weight | About 8.5T |

| 11 | Voltage | 380V 50HZ3 phase |

| 12 | Roll material | GCr15(bearing steel)hard chrome plated after heat treatment |

| 13 | Shaft material | 40Cr Modulation of heat treatment after polishing hard chromium plating |

| 14 | On both sides of the wall material | A3 steel |

| 15 | Frame | International H-beam |

| 16 | Blade material | Cr12Mov |

| 17 | Forming wheel | Bearing steel quenching |

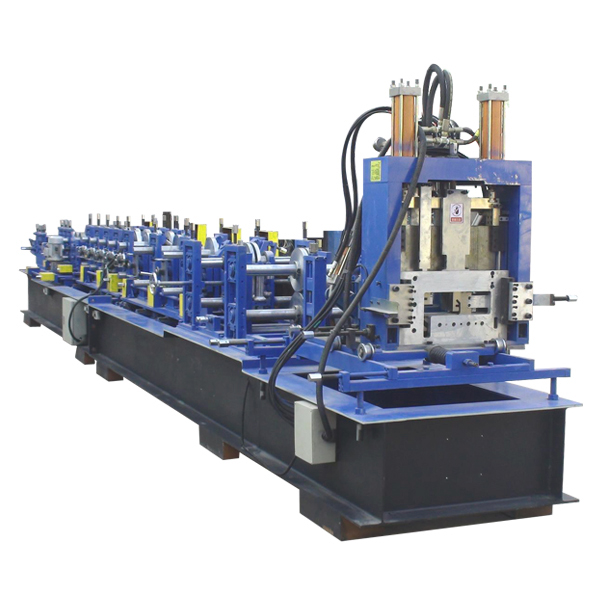

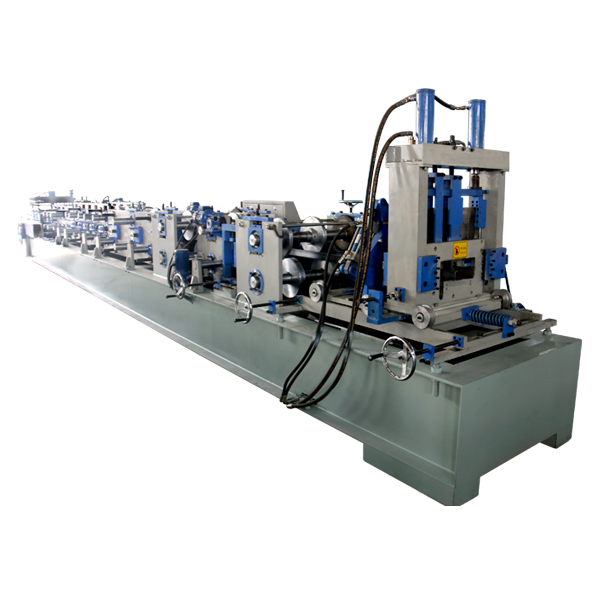

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m)

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit

2. Package: export standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after inspect the machine before delivery)

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

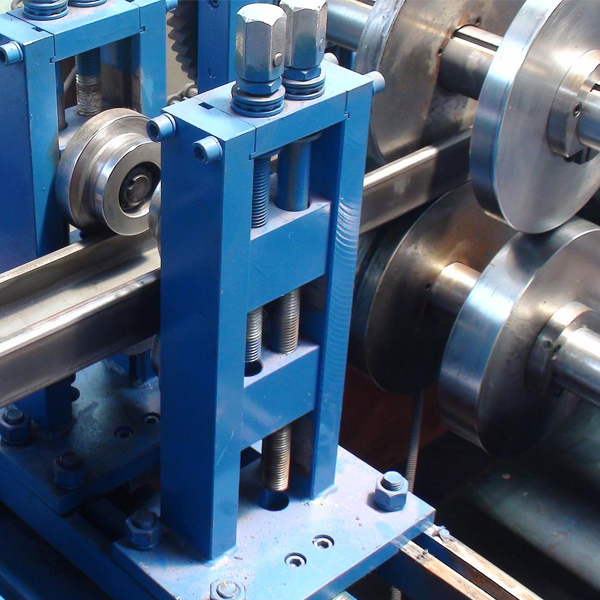

Product detail pictures:

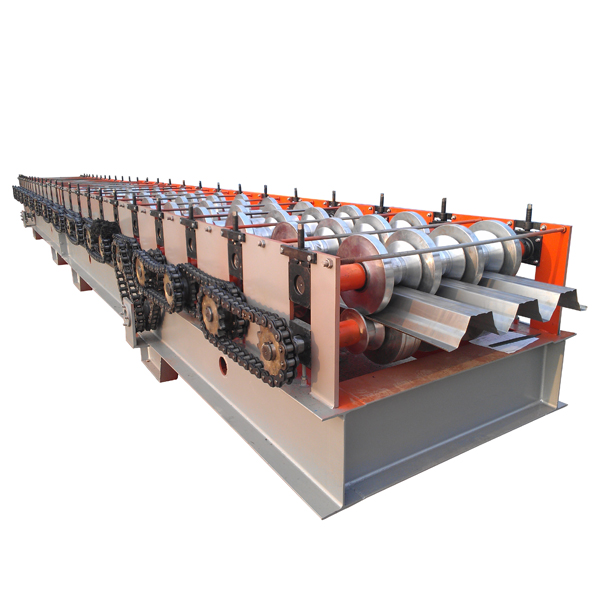

Related Product Guide:

John McCain, War Hero, Senator, Presidential Contender, Dies at 81 | Decoiler In Color Coating Line

Facebook is hosting an online abuse summit with other tech leaders Engadget Engadget save share save share save share save share save share save share ear icon eye icon text file vr | Ibr Roof Sheet Making Machine

Factory Cheap Hot Sandwich Panel Manufacturing Line - OEM/ODM China Steel Roof Truss Making Machinery Metal Roll Forming U C Z Purlin Machines – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

New Arrival China Stone Steel Roof Tile Machine...

-

OEM/ODM Factory Automatic Metal Roofing Sheet B...

-

Online Exporter Cnc Profile Bending Machine - ...

-

Factory For Gutter Cold Rolling Forming Machine...

-

Wholesale Dealers of Bending Metal Machine - W...

-

2017 Latest Design Curved Cladding Sheets Machi...