Good quality comes initial; service is foremost; company is cooperation” is our business enterprise philosophy which is constantly observed and pursued by our organization for Factory Cheap Hot Durable Top Hat C Sheet Roofing Channel Machine/ Stud Track Making Machine, We are looking forward to forming successful business relationship with new clients in the near future!

Good quality comes initial; service is foremost; company is cooperation” is our business enterprise philosophy which is constantly observed and pursued by our organization for Hat Forming Machine, Light Keel Making Machine, Stud Track Making Machine, We would very much welcome an opportunity to do business with you and have pleasure in attaching further details of our solutions. Excellent quality, competitive prices,punctual delivery and dependable service can be guaranteed.

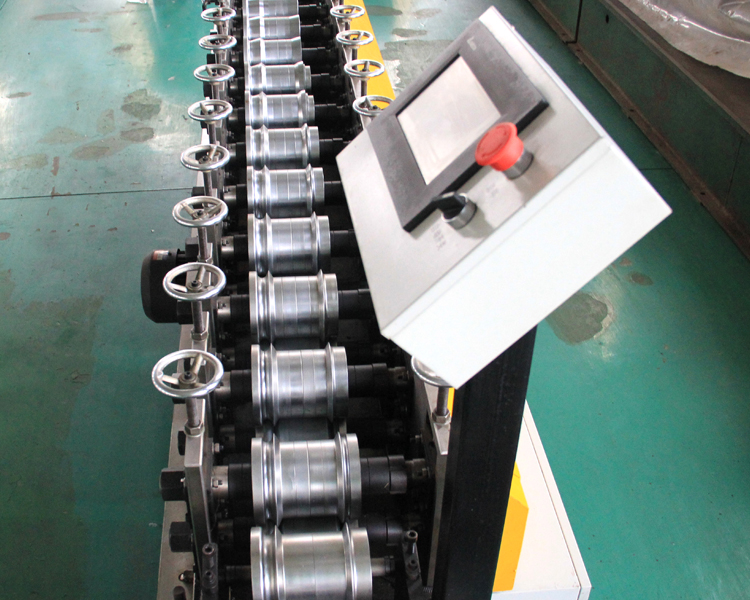

The c channel roll former c keel making machine is the main equipment for the production of light steel. It is formed by cold forming of steel or steel, and is rolled to produce light keels of various specifications.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

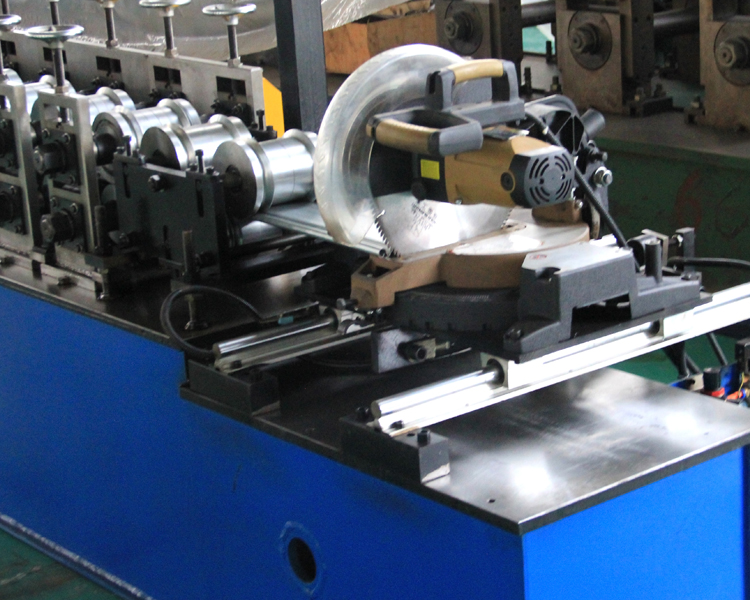

Ceiling c channel making machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Our Service Advantage

1. Professional: rich experience in product and export process!

2. Low price: Save your money from every part!

a. Low labor cost;

b. Convenient transportation;

c. Complete supporting industries.

-

100% Original Factory Stud And Track Light Stee...

-

Factory Cheap Australian Style Hydraulic Cuttin...

-

Short Lead Time for Plc Control System Availabl...

-

2018 Good Quality Steel Door Frame Roll Forming...

-

Professional China Stainless And Aluminum Auto ...

-

ODM Supplier Zl 2500mm Automatic Spring Decoile...