Factory best selling Colorful Stone Coated Steel Roof Tiles Machine/Production Line - Popular Design for 3d Thick Wire Bending Machine Spring Forming Machine For Car Seat Frame And Auto Parts – Haixing Industrial Detail:

Getting buyer gratification is our company’s purpose endlessly. We will make good attempts to produce new and top-quality products, meet up with your specific requirements and provide you with pre-sale, on-sale and after-sale expert services for Popular Design for 3d Thick Wire Bending Machine Spring Forming Machine For Car Seat Frame And Auto Parts, Be sure to experience free to make contact with us at any time. We’re going to reply you when we receive your inquiries. Please note that samples are available before we start our business.

Getting buyer gratification is our company’s purpose endlessly. We will make good attempts to produce new and top-quality products, meet up with your specific requirements and provide you with pre-sale, on-sale and after-sale expert services for 3d Wire Machine, Spring Forming Machine, Wire Bending Machine, We warmly welcome your patronage and will serve our clients both at home and abroad with items of superior quality and excellent service geared to the trend of further development as always. We believe you will benefit from our professionalism soon.

|

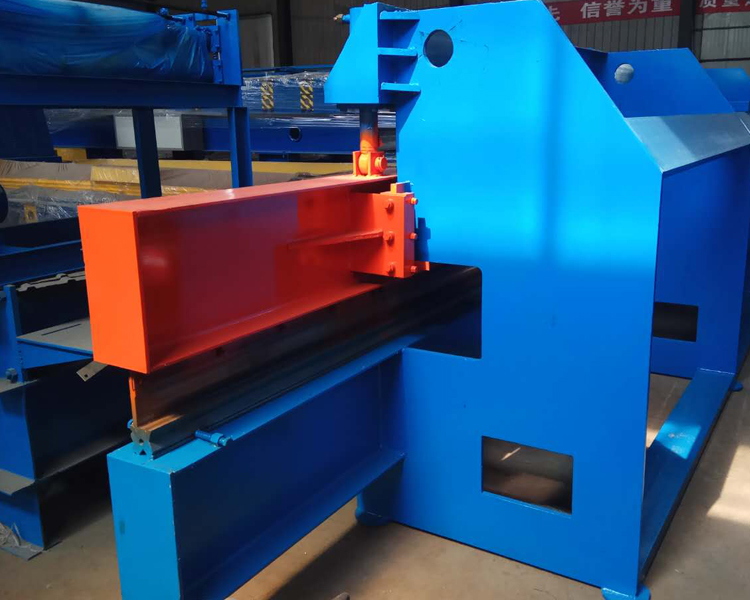

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

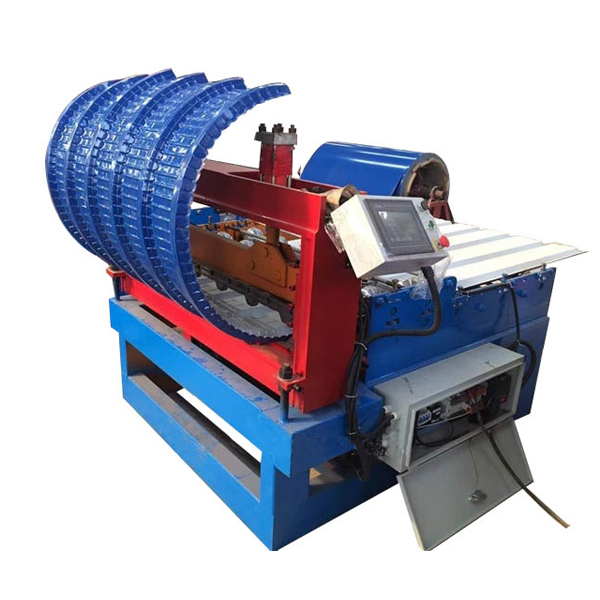

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

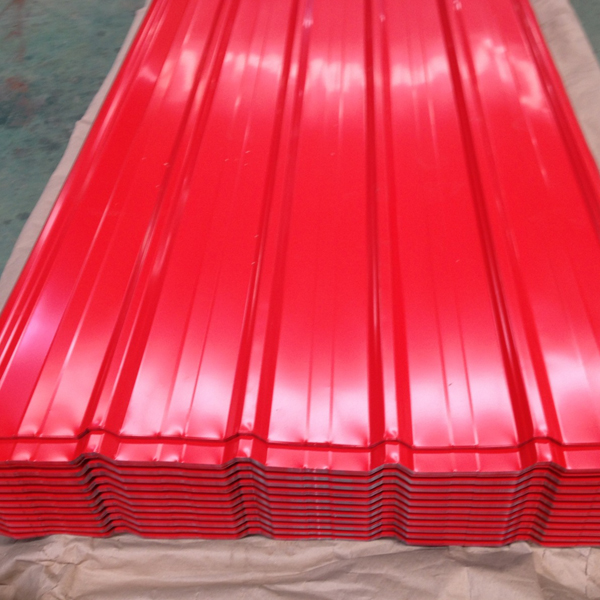

Product detail pictures:

Related Product Guide:

‘She makes children of us all’: Guardian writers pick their favourite Kate Bush lyrics | Music | Decoiler In Color Coating Line

Dexcom G6 latest diabetes monitor doesn’t need blood | Floor Deck Macking Machine

Factory best selling Colorful Stone Coated Steel Roof Tiles Machine/Production Line - Popular Design for 3d Thick Wire Bending Machine Spring Forming Machine For Car Seat Frame And Auto Parts – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Manufacturing Companies for Steel Sheet Glvaniz...

-

Short Lead Time for Metal Roof Sheet Bending Ma...

-

OEM Supply Ordinary Roof Tile Machine - Roof P...

-

OEM Supply Coiler Recoiler - Aluminized Trapez...

-

Hot sale Factory Gi Bending Machine - Metal cu...

-

Well-designed Rain Gutter Metal Downspout Cold ...