We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Factory best selling Aluminum Roof Tile Sheet Portable Roll Forming Machines, We have now experienced manufacturing facilities with a lot more than 100 workers. So we are able to guarantee short lead time and good quality assurance.

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate inside our success for Aluminum Roll Forming Machine, Portable Roll Forming Machines, Roof Tile Sheet Rolling Forming Machine, For anyone who is keen on any of our merchandise right after you view our product list, be sure to really feel absolutely free to get in touch with us for inquiries. You are able to send us emails and contact us for consultation and we shall respond to you as soon as we can. If it’s easy, you may locate out our address in our web-site and come to our business for far more information of our merchandise by your self. We are always ready to construct extended and steady co-operation relations with any possible customers in the related fields.

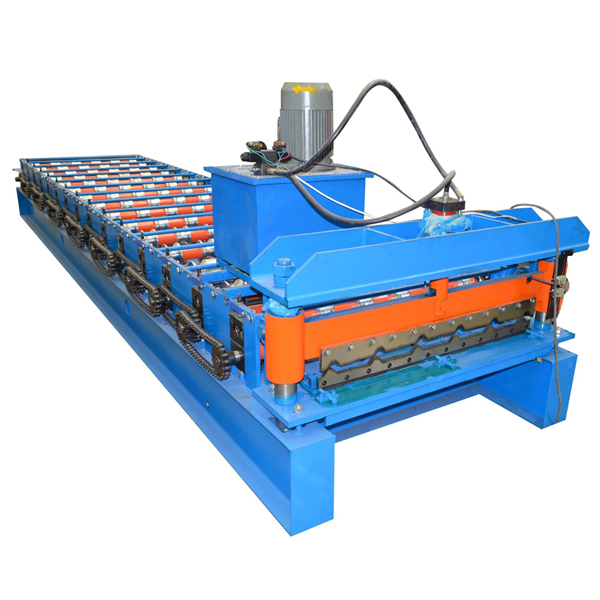

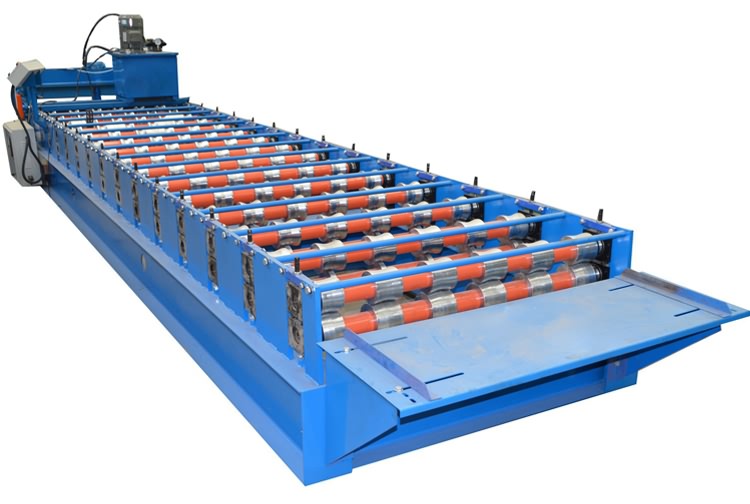

Aluminum trapezoidal roof making machine can uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate.

|

Aluminum Trapezoidal Roof Making Machine Parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Detail of machine:

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

China New Product Pipe Metal Tube Steel Slittin...

-

Europe style for Roof Used Metal Steel Roof Pan...

-

Fixed Competitive Price China Factory Sales Cor...

-

Best Price on Color Steel Galvanized Metal Trap...

-

Renewable Design for China Quick Change Size Ty...

-

OEM Customized Metal Stud Roll Forming Machine ...