We usually believe that one’s character decides products’ high quality, the details decides products’ excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Europe style for Roof Used Metal Steel Roof Panel Frame Forming Machine, Welcome all clients of dwelling and abroad to go to our corporation, to forge a fantastic long term by our cooperation.

We usually believe that one’s character decides products’ high quality, the details decides products’ excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Cd Ud Roll Forming Machine, Forming Machine For Used Metal Roof Panel, Light Steel Keel Roll Forming Machine, Profession, Devoting are always fundamental to our mission. We’ve got always been in line with serving customers, creating value management objectives and adhering to the sincerity, dedication, persistent management idea.

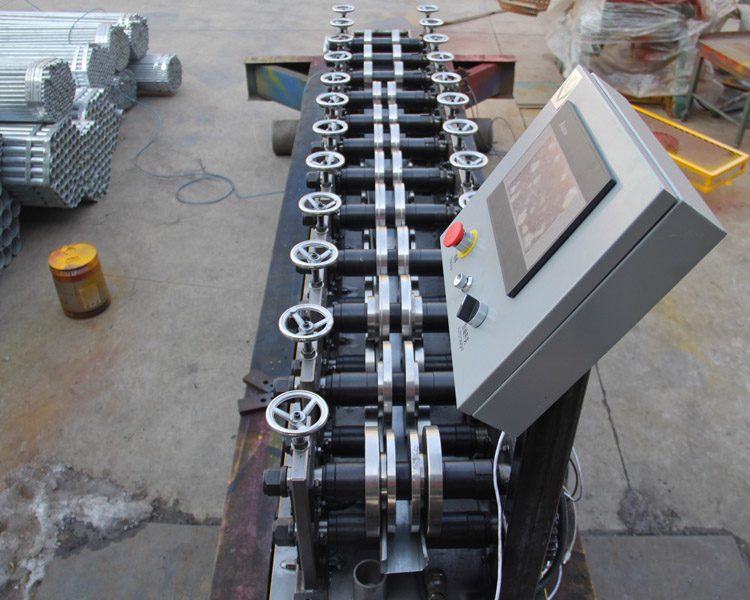

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Factory wholesale Hydraulic Sheet Metal Decoile...

-

New Arrival China Different Types Ibr And Corru...

-

New Fashion Design for hydraulic press metal ro...

-

China OEM Full Automatic Double Layer Roofing S...

-

China Wholesale Galvanized,Zinc Corrugated Meta...

-

Super Lowest Price Mobile Standing Seam Roof Pa...