We also offer you product sourcing and flight consolidation expert services. We’ve our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Europe style for Large Diameter Pipe And Tube Bending Machine, By 10 years effort, we attract consumers by aggressive cost and exceptional service. Moreover, it really is our sincere and sincerity, which assistance us always be clients’ first choice.

We also offer you product sourcing and flight consolidation expert services. We’ve our personal manufacturing unit and sourcing business. We can offer you virtually every variety of merchandise associated to our item range for Big Diameter Tube And Pipe Bending, Large Diamter Bending Machine For Pipe, Pipe Bending Machine, Aiming to grow to be by far the most expert supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal items. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you’ll be served with good quality consultant service by our after-sale team. They’re likely to make it possible for you to get complete acknowledge about our products and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

|

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

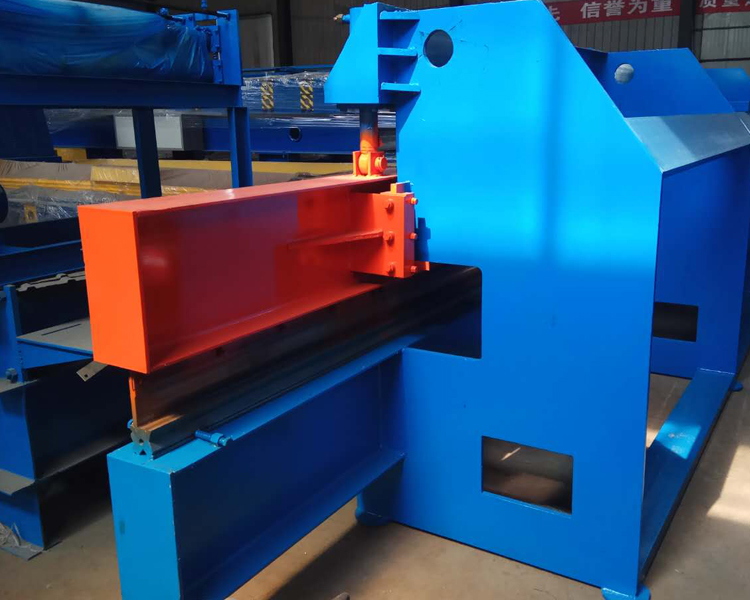

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Professional Design China Metal Framing Rolling...

-

ODM Supplier Slitting Line Machine In Other Pac...

-

China Supplier Light Steel Angle Bar Roll Formi...

-

Bottom price Color Coated Corrugated Ridge Cap ...

-

Renewable Design for Judu Cnc Sheet Metal Bendi...

-

Cheap PriceList for China Tile Roof Forming Dou...