This machine can produce two different types of metal tile products. The upper layer of the machine can form glazed tiles, and the lower layer of the machine can form corrugated tiles. The final product is as follows:

Double layer roof forming machine glazed and corrugated roof tile Technical Parameters (some depend on the final design)

| Style | Bolivia glazed & corrugated roof tile double layer roof sheet roll forming machine |

| Machine dimension | 7500*1600*1650mm |

| Total wight | 5800kgs |

| Forming steps | Up layer: 11rows Down layer: 13rows |

| Forming speed | Glazed design: 1.5-3.0m/min Wave design: 10-15m/min |

| Hydraulic station power | 4kw |

| Diameter of shaft | 70mm |

| Hydraulic pressure | 18-20 MPa |

| Electric condition(Voltage ) | 380V/3Phase/ 50HZ (or based on customer’s need ,for example: 220V 440V 415V or 2Phase 60HZ ) |

| Suitable to process | Color steel plate(G330 or G350 ) galvanized steel coil |

| Manual uncoiler max capacity | 5000kgs |

| Control system | PLC |

| Raw material thickness | 0.3-0.8mm |

| Effective width | 800mm and 836mm |

| Material width | 1000mm and 1000mm |

| Main motor | 5.5Kw |

| Material of the cutting blade | Cr 12 quenched treatment 58℃-62℃ |

| Main Shaft Material | 45# steel with finish turning |

| Roller materials | 45# Forging Steel with Chromium Plate |

| Machine Under Frame | 400 H beams and sidewall 18mm |

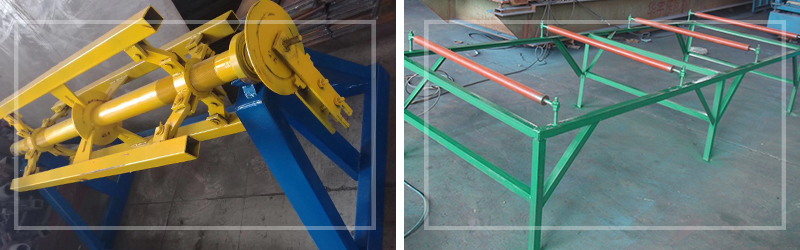

Components of double layer roof roll forming machine

| Manual uncoiler | 1 set | Post-cutting equipment | 1 set |

| Sheet guiding equipment | 1 set | Hydraulic station | 1 set |

| Roll forming system | 1 set | Electric controlling system | 1 set |

| Pressing device | 1 set | Support table | 2 pieces |

We offer our customers easy-broken parts for free.

Application

Roof roll forming machinery could produce metallic roofing tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z purlin, expressway guardrail, channel and stud, roller shutter and sandwich panel, etc. Customized profiles and requirements are acceptable, and assistant equipment such as hydraulic decoiler, auto stacker, etc.

Packaging & Shipping

1. glazed roof tile double layer roof sheet roll forming machine and uncoiler are nude packing (If you need, we can also packed it with water-proof plastic)

2. PLC control system and motor pump are packed with waterproof paper, spare parts in a carton box.

3. One set of machine needs a 40′ container to shipping.

Our company

We are professional! Our factory has extensive experience in product and export processes.

Our machine is the best machine! PLC uses well-known brands to ensure high precision and easy operation.

Our machines are fully automatic: you only need to enter the length of the steel plate and the required number of pieces, the machine will run automatically.

FAQ

Q: How is this machine’s service life?

A: In the normal maintenance, the service life at least 8 years.

Q: Can you be responsible for transport?

A: Yes, please tell me the destination port or address. We have rich experience in transport.

Q: Can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

Q: How many workers operate this machine to manufacture?

A: Only 1-2 worker.

Q: Can you supply the raw materials?

A: Yes, we can supply the galvanized steel coil, galvalume steel coil, color steel coil, and aluminum coil.

Q: Why choose your company’s products?

A: Because of our products cost-effective, not only high quality and affordable.

Q: Are you a trading company or a factory?

A: We are factory with the professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: How long does it take to produce the machine?

A: Generally speaking, the machine can be completed within 20~45 working days. But if you need machines urgently, we can do our best to save you time.