We support our consumers with ideal high-quality goods and substantial level support. Becoming the specialist manufacturer in this sector, we now have acquired abundant practical encounter in producing and managing for Discountable price China Cold Room Sandwich EPS Panel Production Line Roll Forming Machine, In a word, when you choose us, you choose a ideal existence. Welcome to visit our factory and welcome your get! For even further inquiries, remember to usually do not hesitate to make contact with us.

We support our consumers with ideal high-quality goods and substantial level support. Becoming the specialist manufacturer in this sector, we now have acquired abundant practical encounter in producing and managing for China Sandwich Panel Machine, Sandwich Panel Line, With the first-class products and solutions, excellent service, fast delivery and the best price, we have now won highly praise foreign customers’. Our products have been exported to Africa, the Middle East, Southeast Asia and other regions.

PU Sandwich panel as a kind of construction material is widely used in construction, heat preservation, packaging, frozen, daily necessities, industrial casting, etc.

It can also be used to display the assembly places, commodity cabinet, signs and toys manufacture.

|

PU Sandwich Roof Roll Forming Machine parameters |

||

|

1 |

Equipment overall dimensions |

30m*2.6m*3m |

|

2 |

Total weight |

About 16 ton |

|

3 |

Control system |

Omron encoder PLC |

|

4 |

Main motor power |

Planetary cycloid reducer, 4kw, 380V, 50HZ |

|

5 |

Processing speed |

4~4.5 m/min, continuous stepless adjusted, variable frequency speed regulation, digital display |

|

6 |

raw material |

1.2 meters |

|

7 |

Voltage |

380V |

|

8 |

Roller material |

chrome plated on 45# steel forgings |

|

9 |

Number of rubber shafts |

27 foams, 39 rock wool |

|

10 |

Total power |

30 kw |

|

11 |

Synchronous controller |

Digital synchronous controller |

|

12 |

Corrugated press motor power |

Double-stage cycloid reducer 4kw, 380V, 50HZ |

|

13 |

Application |

roof panel, wall panel |

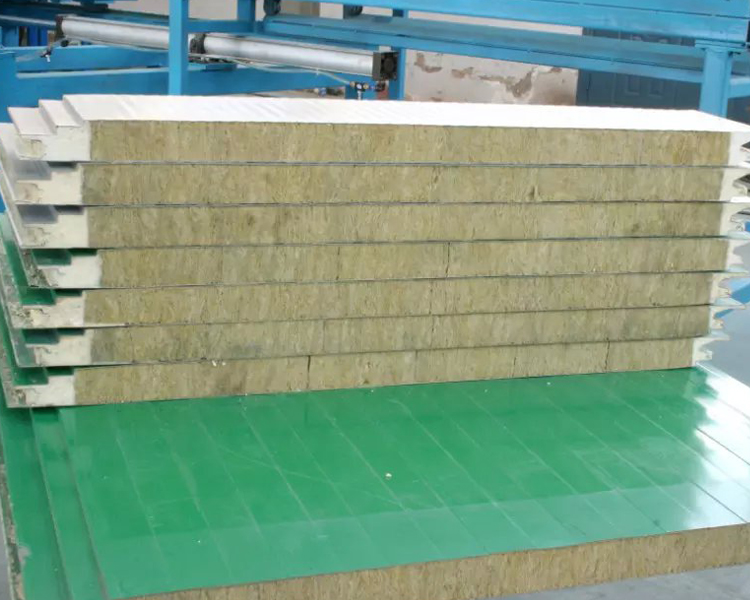

Machine picture display

Packaging and Shipping

1) Tighten the container with a wire rope and weld the container to the container with natural iron.

2) Main forming machine and un-coiler is naked (we can also use waterproof plastic packaging if needed).

3) PLC control system and motor pump are packed in wooden box with water proof paper coverage.

-

Low price for Low Cost C Channel Steel Light St...

-

High reputation Laser Cutter 1325 1390 Cnc Wood...

-

Special Design for China Light Steel Keel Drywa...

-

100% Original Hot Sale Durable Steel Frame Ligh...

-

100% Original 2019 New Products Self-acting Til...

-

Factory For China Double Layer Galvanized Corru...