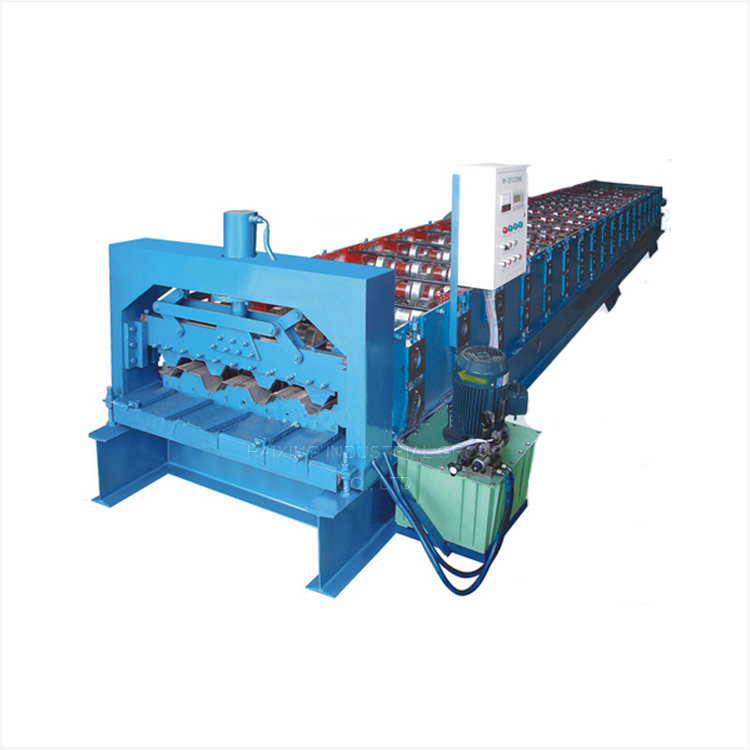

This machine used to make Floor deck plate, usually, we used to construction for floorboards, rolled into the floorboards after its V-shaped cross-section into categories U type, a ladder or a combination of several shapes, mainly used to make permanent from work composite slab or concrete slab.

The main technical parameters of Decking Floor Plate Making Machine

| Main Frame | welded with 450H steel |

| Middle plate | 18mm |

| Forming machine guide feeding frame form | side roller type |

| Forming machine form | wall plate chain drive |

| Shaft diameter | ¢95 mm |

| Chain size | 1.5 inches (Brand “Zhenghe” Imported Japan sprocket) |

| Roll forming machine motor power | 2-15KW (Brand Siemens) |

| Roll forming speed | 8-12m/min |

| Rollers number | 27Rows |

| Rolling material | high grade 45# forging steel with chromium plate |

| Hard chrome plating on the roll surface | 0.03mm |

| Hydraulic pump motor | 4KW (Lichao, Shanghai ) |

| Hydraulic station oil pump | gear pump |

| Cutting method | connecting rod three-knife hydraulic cutting |

| The material of the cutting blade | Cr12 |

| Cutting blade heat treatment | quenched treatment 58℃-62℃ |

| Rolling raw materials thickness | 0.7-1.2mm |

| Length Tolerance | ± 2mm |

| Electric control box configuration | inverter (anchuan), PLC (Panasonic), encoder (OMRON), Other electrical components are “Schneider” brand |

Decking Floor Plate Making Machine details

Application of decking floor tiles

Floor decking board products are widely used in power plants, power equipment companies, automobile exhibition halls, steel structure workshops, cement warehouses, steel structure offices, airport terminals, railway stations, stadiums, concert halls, grand theaters, large supermarkets, logistics centers, steel structures such as Olympic venues and stadiums.

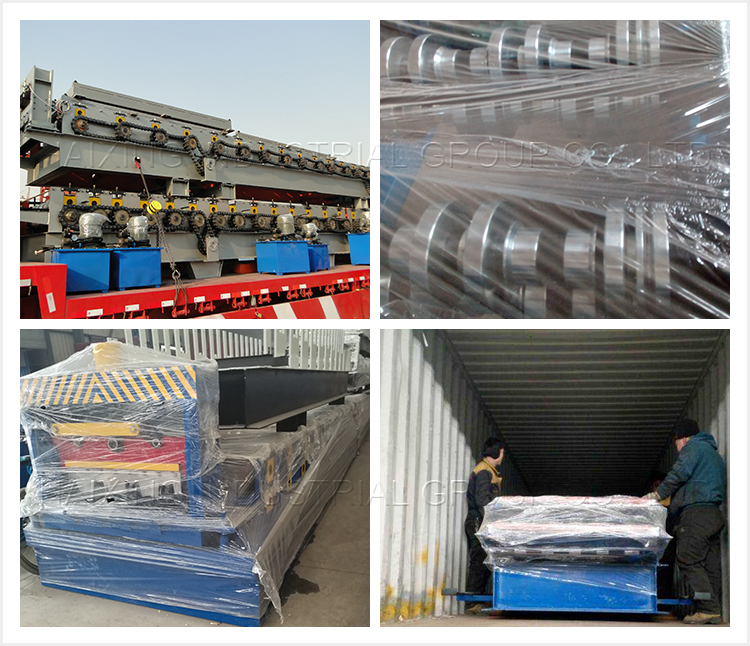

Decking Floor Plate Making Machine Packaging & Shipping

1. 40 feet container;

2.PVC film package;

3. according to customer requirement.

-

10 Ton Hydraulic Decoiler With Coil Car

-

1xxx 3xxx 5xxx Series Aluminium Coil

-

1020 Trapezoidal Roof Sheet

-

1100mm steel tile roofing sheet roll forming ma...

-

2019 High Quality Glazed Tile Making Machinery ...

-

762 Corrugated Roof Metal Sheet Roll Forming Ma...

-

Roof tile making sheet metal machine aluminum d...

-

1000 Trapezoidal Metal Sheet Roll Forming Machine

-

2019 Hot Dipped Galvanized Steel Coil

-

6m Steel Bending Machine

-

762 Hot Sale aluminium wall sheet used metal ro...