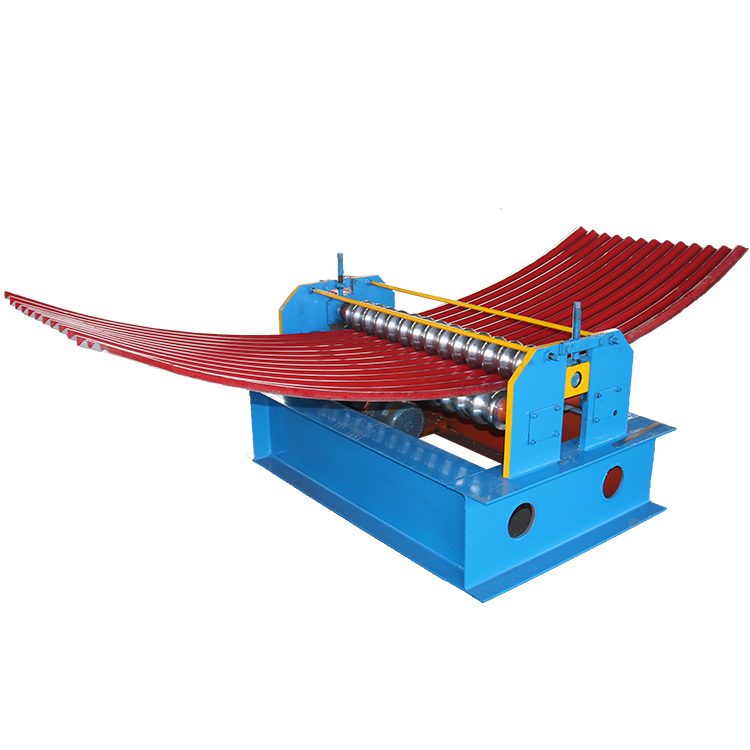

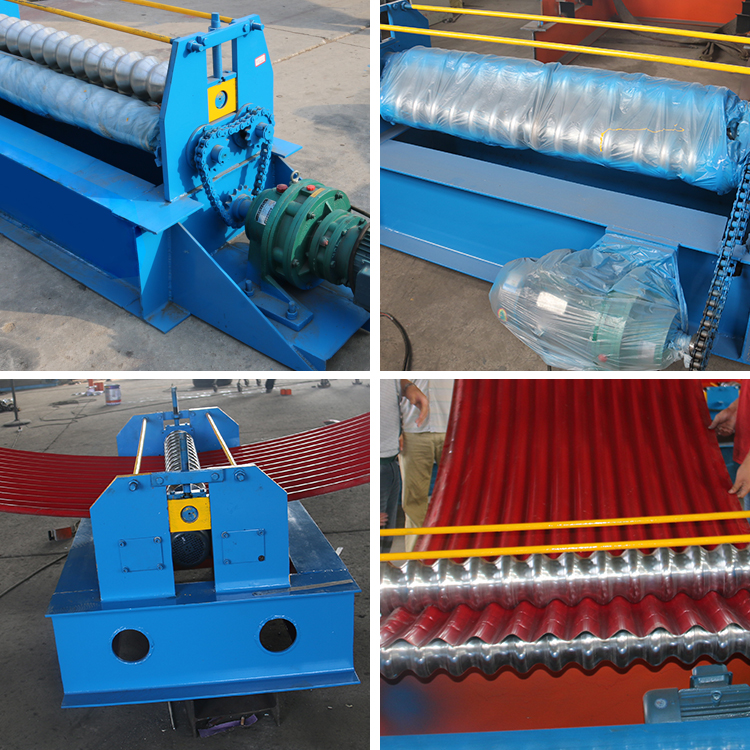

Curved Corrugated Roof Panel Roll Forming Machine parameters

| Mainframe | Welded from 350mm H-beam. |

| Roller shaft diameter | 70mm, solid shaft with retaining pad, shaft material is 45# steel chrome 0.03mm. |

| Transfer method | 1.0 inch chain |

| Medium plate thickness | 16mm |

| Main motor | 3kw, Siemens Bede Motor |

| Hydraulic power station | 4kw, gear pump: Shanghai Lichao |

| Cutter material | Cr12, heat treatment HR50-60 |

| Cutting method | Hydraulic four-column cutting |

| Length tolerance | ±2mm |

| PLC | High-precision computer control cabinet: Taiwan Delta; touch screen, frequency converter: Mitsubishi |

The random attachments of Curved Corrugated Roof Panel Roll Forming Machine

1, Ordinary loading frame and 1 core.

2, Receiving table: 1

3, Easy-broken parts: counter wheel (1), bearing (4), hydraulic oil pipe (2 pieces), solenoid valve (1), limit switch (2), button (2 pieces)

Curved Corrugated Roof Panel Roll Forming Machine photos

FAQ

How can we be assured that you will deliver us quality machine with spare parts?

1. Customers to send the technical people to our factory for checking the quality.

2. We can send the technicians to the buyer`s factory for the installation of the machine.

3. Good aftersales-service, its free of charge during the warranty period.

How to play order?

Inquiry—confirm the profile drawings and price—-confirm the PI—arrange the deposit or L/C—then OK