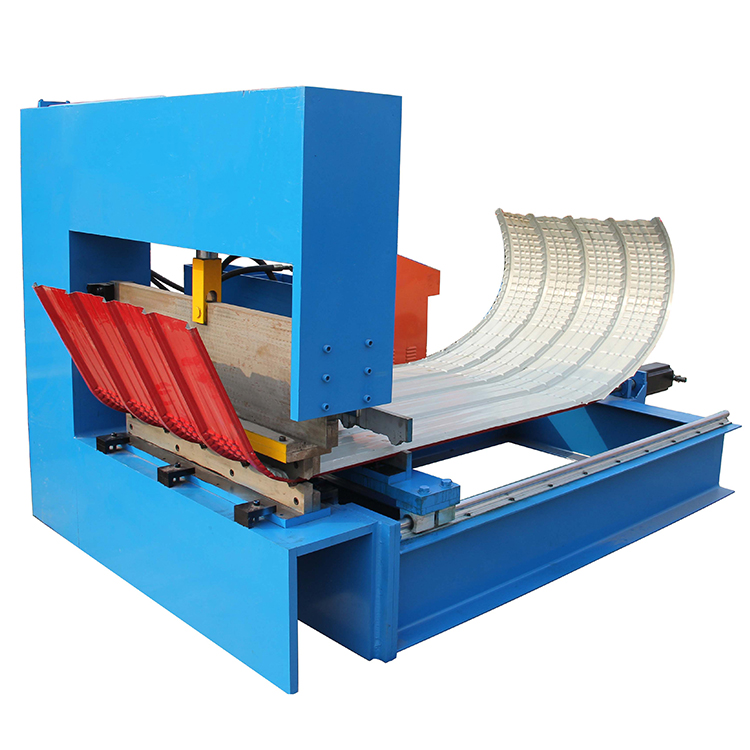

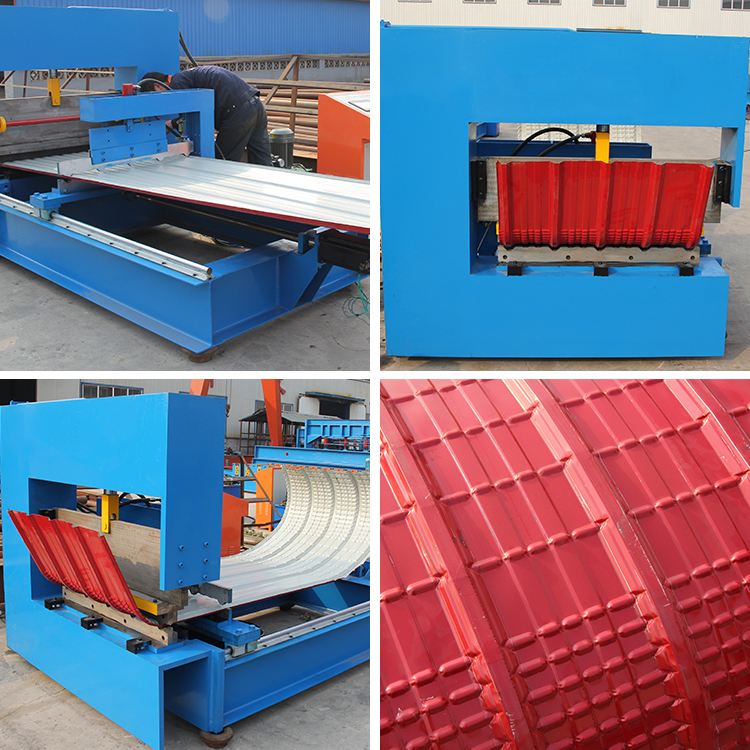

Curved Cladding Sheets Machine parameters

| 1 | Mainframe | Welded from 350mm H-beam. |

| 2 | Roller shaft diameter | 70mm, solid shaft with retaining pad, shaft material is 45# steel chrome 0.03mm. |

| 3 | Transfer method | 1.0 inch chain |

| 4 | Medium plate thickness | 16mm |

| 5 | Main motor | 3kw, Siemens Bede Motor |

| 6 | Hydraulic power station | 4kw, gear pump: Shanghai Lichao |

| 7 | Cutter material | Cr12, heat treatment HR50-60 |

| 8 | Cutting method | Hydraulic four-column cutting |

| 9 | Length tolerance | ±2mm |

| 10 | PLC | High-precision computer control cabinet: Taiwan Delta; touch screen, frequency converter: Mitsubishi |

The random attachments of Curved Cladding Sheets Machine

1, Ordinary loading frame and 1 core.

2, Receiving table: 1

3, Easy-broken parts: counter wheel (1), bearing (4), hydraulic oil pipe (2 pieces), solenoid valve (1), limit switch (2), button (2 pieces)

Curved Cladding Sheets Machine photos

FAQ

1)Q: Do you have after-sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly.

3)Q: How does your factory do regarding quality control?

A: Quality is priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.

-

1080mm design trapezoid roof tile making machine

-

C Light Steel Keel Roll Forming Machines

-

Roof tile making sheet metal machine aluminum d...

-

10 Ton Hydraulic Decoiler With Coil Car

-

201 Steel Cold Roll Stainless Aluminum Coil

-

4 Meters Hydraulic Roof Sheet Bending Machine

-

690mm Galvanized Steel Sheet Floor Decking Pane...