Curve Roof Roll Forming Machine parameters

| Electric tension | 380V 3phase 50HZ or as the customer’s requirements |

| Material of roller | High-grade 45# forged steel plated with hard chrome plating |

| Controlling system | PLC |

| Processing speed | 3-6m/min |

| Processing precision within | 1.00mm (depend on design) |

| Material of cutting blade | Cr12 mold steel with quenched treatment |

| Roller station | 8-20 Rollers |

| Roller material | high grade 45#steel; Cr12 quenching |

| Leak frame load-bearing | 4.6T |

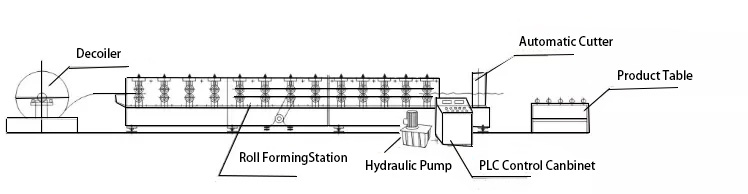

Curve Roof Roll Forming Machine production process

Curve Roof Roll Forming Machine Applications

The curved panels produced by Curve Roof Roll Forming Machine are used for the door and wall.

Our products include roof roll forming machines, Leveling and shearing machines, decoilers, c&z purlin roll forming machines, slitting lines, Light steel keel roll forming machines and other associated equipment.

FAQ

Q: What can you do if the machine is broken?

A: The warranty period of our machine is 14 months, if the damaged parts can not be repaired, we can send new parts to replace the damaged parts for free, but you need to pay the courier fee yourself. If after the warranty period, we can resolve the issue through negotiation, we provide technical support for the entire life cycle of the device.

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: How long does it take to produce the machine?

A: Generally speaking, the machine can be completed within 20~45 working days. But if you need machines urgently, we can do our best to save you time.

-

1080mm design trapezoid roof tile making machine

-

C Light Steel Keel Roll Forming Machines

-

Roof tile making sheet metal machine aluminum d...

-

10 Ton Hydraulic Decoiler With Coil Car

-

1000 Trapezoidal Metal Sheet Roll Forming Machine

-

1xxx 3xxx 5xxx Series Aluminium Coil

-

4 Meters Hydraulic Roof Sheet Bending Machine