crimping curved arch roll forming machine parameters

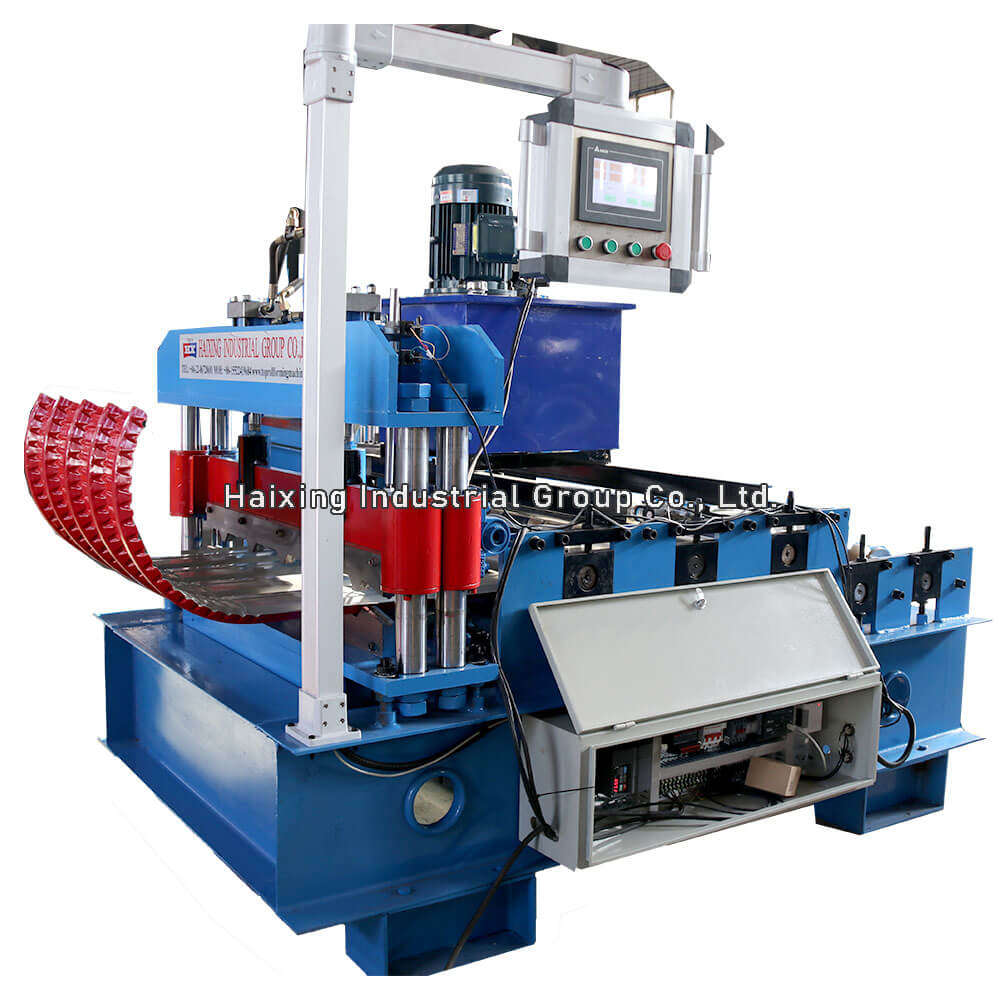

crimping curved arch roll forming machine pictures

Packing & Shipping

a.The main body of crimping curved arch roll forming machine with water-proof plastic, then fixed to container by 8mm diameter steel wire and angle iron.

b.Rollers and shafts are covered with anti-rust oil.

c.PLC control system and motor pump are packed with waterproof paper and plastic film.

d.Spare parts in a carton box.

e.Manual decoiler was nude packing.

f.The output-table put into a carton box.

g.If the machine is too long, we will divide it into two parts and pack them in one package with steel wire.

h.Fit for ocean shipping.