Crimp Curved Roofing Sheet Making Machine parameters

| Suitable material | Color steel sheet, galvanized steel sheet, aluminum sheet |

| Installation Dimension (L*W*H): | 6.5m*1.5m*1.4m |

| Main motor power | 3KW with Cycloidal reducer |

| Hydraulic station power | 3KW |

| Hydraulic oil pump | CB-E 310 |

| Thickness of material | 0.2mm~0.8mm |

| Diameter of the principal axis | Φ70-90mm |

| Material expands width | 1000,1200,1250mm |

| Electric tension | 380V 3phase 50HZ or as the customer’s requirements |

| Material of roller | High-grade 45# forged steel plated with hard chrome plating |

| Controlling system | PLC |

| Processing speed | 3-6m/min |

| Processing precision within | 1.00mm (depend on design) |

| Material of cutting blade | Cr12 mold steel with quenched treatment |

| Roller station | 8-20 Rollers |

| Roller material | high grade 45#steel; Cr12 quenching |

| Leak frame load-bearing | 4.6T |

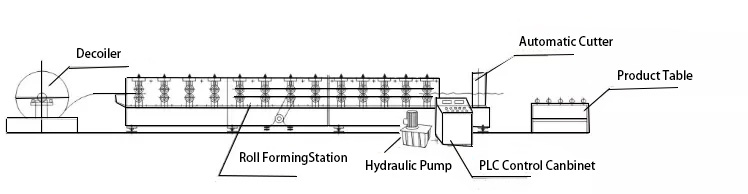

Crimp Curved Roofing Sheet Making Machine production process

Crimp Curved Roofing Sheet Making Machine Applications

The curved panels produced by Crimp Curved Roofing Sheet Making Machine are used for the door and wall.

Our products include roof roll forming machines, Leveling and shearing machines, decoilers, c&z purlin roll forming machines, slitting lines, Light steel keel roll forming machines and other associated equipment.