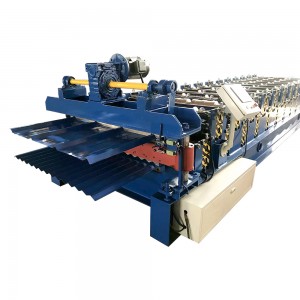

Corrugated trapezoidal double layer roof forming machine parameters

| 1 | Main motor power | 4kW/5.5KW/7.5KW |

| 2 | Hydraulic motor power | 3kW/4kw |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC control system |

| 6 | Mainframe | 350/400 H-beam |

| 7 | Backboard thickness | 16mm/18mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm, or as profile |

| 13 | Productivity | 0-30m/min (motor drive can arrived 25m/min to 30m/min) |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components of Corrugated trapezoidal double layer roof forming machine:

Manual uncoiler: 1 set

Guiding platform: 1 set

Coil leveler: 1 set

Roll forming parts: 2 sets

Electric-motor: 1 set

Cutting device: 2 sets

Hydraulic station: 1 set

PLC control: 1 set

Output Supporter table: 1 set

Details of double layer roof forming machine

Packing & delivery photos

FAQ:

Q:How is this machine’s service life?

A:In the normal maintenance, the service life at least 8 years.

Q:Can you be responsible for transport?

A:Yes, please tell me the destination port or address. We have rich experience in transport.

Q:can you make the machine according to my design or prototype?

A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.