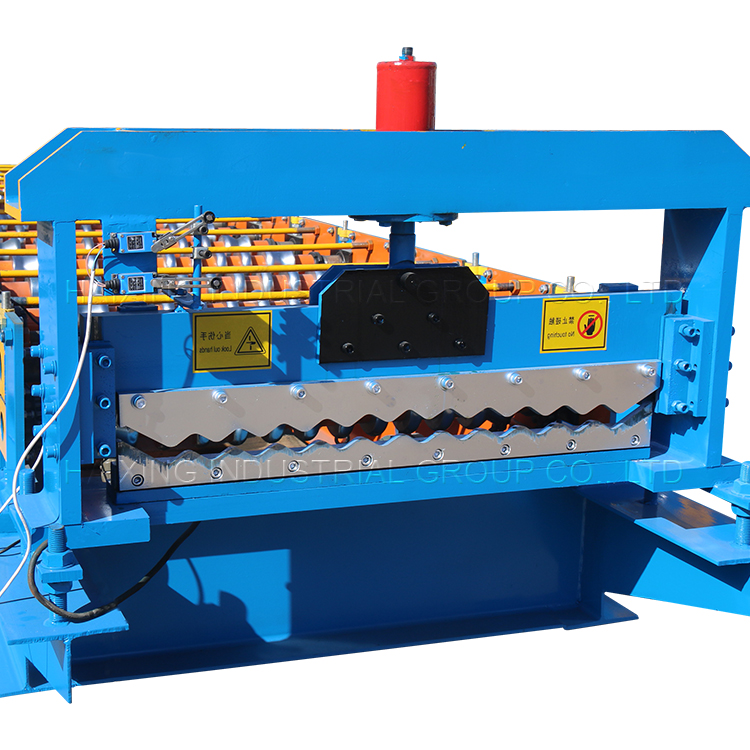

Corrugated Roof Metal Sheet Cold Roll Forming Machine parameters:

| 1 | Main motor power | 4kW, 3 phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Main frame | 300/350 mm H-beam |

| 7 | Backboard thickness | 16 mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0-15/ min |

| 12 | Roll station | 13 roll steps (according to different design) |

| 13 | Roller diameter | 70 mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12 |

| 16 | Cr-plating size | 0.05 mm |

Different parts of the machine:

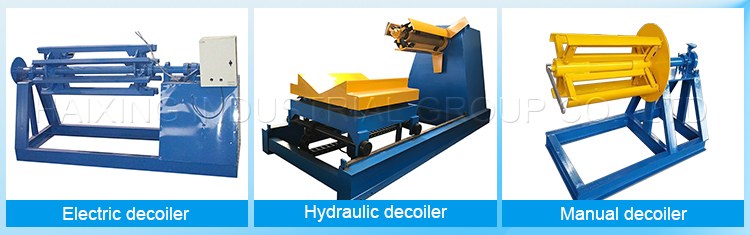

Decoiler: the common machine with 5 tons manual decoiler or you also can choose electric decoiler or hydraulic decoiler.

PLC control console:

Roll forming parts and Output table:

Cutting parts: common is hydraulic pump drive cutting or you can choose electric motor drive cutting as follows:

Easy-broken parts:

Our Advantage:

1. Our machine motor is GERMAN BRAND SEMENS;

2. Our roller spacer is 4 mm thick seamless steel pipe;

3. Our output table can adjust the height according to customer demands;

4. Our PLC control console can look around 360 degrees;

5. All easy-broken pars can be changed within 14 months in free.

Packaging Details:

1. The main machine is covered by the plastic film.

2. PLC control box, spare parts, and other small parts are packed by wooden carton box.

Sales Service:

1. We provide the technical support for the whole life of our roof roll forming machines.

2. If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost, including visa, round trip ticket, etc.

All products of our company and their applications:

A. Roll forming machinery: which could produce metallic roofing tile, trapezoidal or sinusoidal roofing sheet, floor deck, C and Z purlin, expressway guardrail, channel and stud, roller shutter and sandwich panel, etc. Customized profiles and requirements are acceptable, and assistant equipment such as hydraulic decoiler, auto stacker, etc.

B. Steel structure Building: Complete service including design, fabrication, delivery and installation supervision for PEB industry, such as the warehouse, workshop, shopping mall, highrise building, etc.

C. Related products: Metal material for PEB building and other related equipment, like H-beam process machinery, slitting/CTL machine, etc.