Competitive Price for Double Layer Roll Forming Machine - Corrugated Automatic Roof Tile Machine – Haixing Industrial Detail:

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

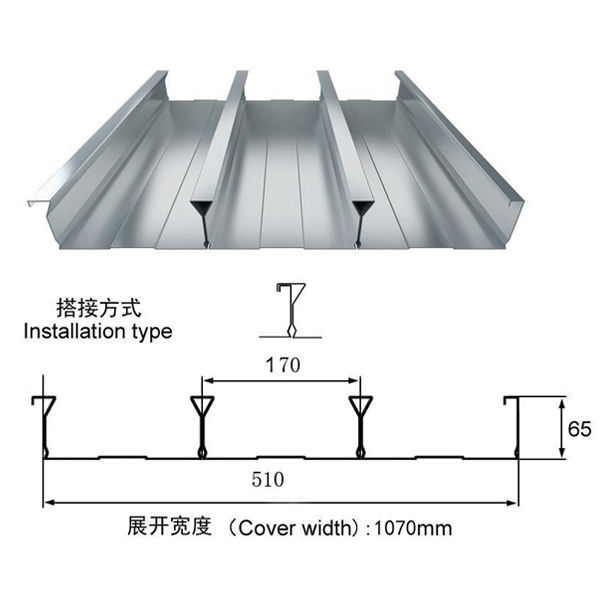

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

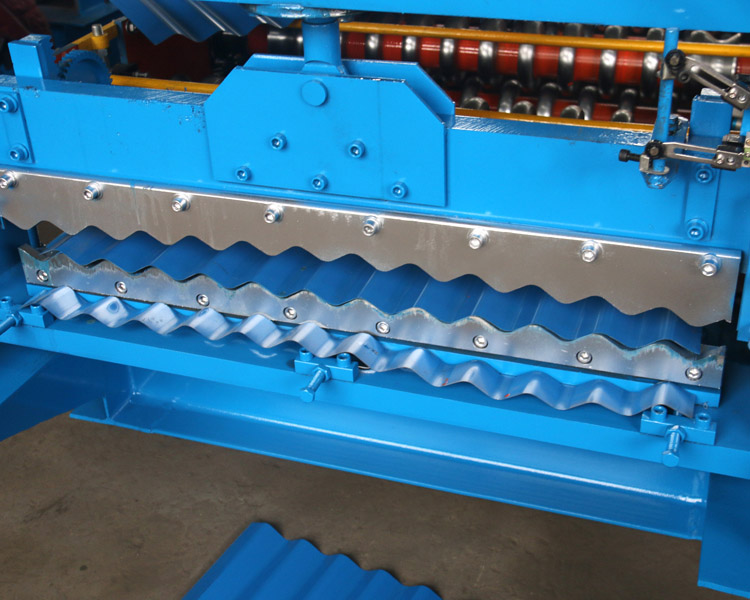

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Product detail pictures:

Related Product Guide:

NFPA-502 Fire Protection Case Histories: Elizabeth River Tunnel and the Hugh L. Carey Tunnel | Roof Sheet Curving Machine

Facebook is hosting an online abuse summit with other tech leaders Engadget Engadget save share save share save share save share save share save share ear icon eye icon text file vr | Ibr Roof Sheet Making Machine

Competitive Price for Double Layer Roll Forming Machine - Corrugated Automatic Roof Tile Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Manufacturer for Used Downspout Roll Forming Ma...

-

OEM manufacturer Sheet Metal Slitter Machine -...

-

PriceList for Water Gutter Cold Roll Forming Ma...

-

Manufacturer of Garage Door Frame Machine - St...

-

Short Lead Time for Rain Spout Gutter Roll Form...

-

Original Factory Ceiling Cross T Grid Roll Form...