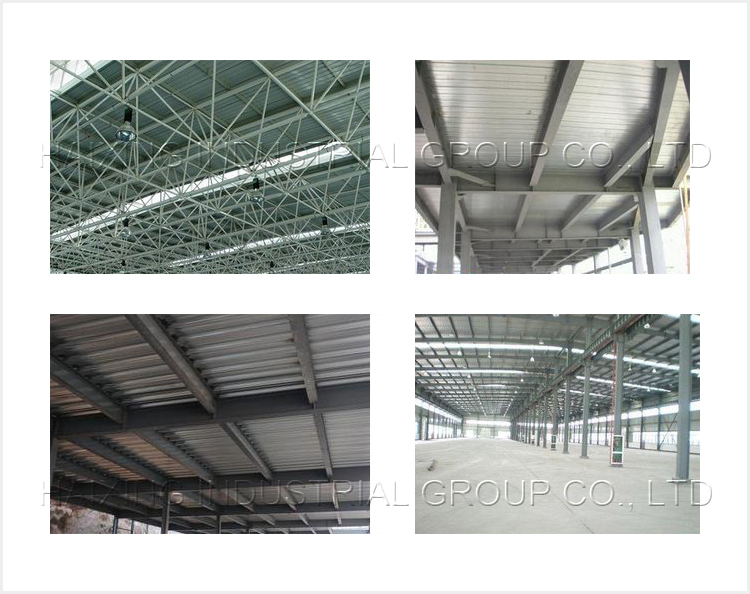

Applications of Color Steel Automatic Floor Deck Tile Forming Machine:

The finished products of Color Steel Automatic Floor Deck Tile Forming Machine are widely used in floor flat, after make embossing of the sheet, it will increase the strength between the steel and concrete, thereby increasing the floor of the fastness.

Color Steel Automatic Floor Deck Tile Forming Machine main technical parameters:

|

Main Frame |

welded with 450H steel |

|

Middle plate |

18mm |

|

Forming machine guide feeding frame form |

side roller type |

|

Forming machine form |

wall plate chain drive |

|

Shaft diameter |

¢95 mm |

|

Chain size |

1.5 inches (Brand “Zhenghe”Imported Japan sprocket) |

|

Roll forming machine motor power |

2-15KW (Brand Siemens) |

|

Roll forming speed |

8-12m/min |

|

Rollers number |

27Rows |

Process Flow of Color Steel Automatic Floor Deck Tile Forming Machine:

Uncoiler -Feeding -Straightening-Roll Forming -Cutting-Exit Rack

Features of Color Steel Automatic Floor Deck Tile Forming Machine:

The metal deck produced by floor decking roll forming line has high strength with big wavelength.

It is used with concrete. Used in high-rise buildings, not only can save steel formwork, but also reduce the weight of the floor. With the same load carrying capacity, it saves steel and reduces investment accordingly.

Color Steel Automatic Floor Deck Tile Forming Machine details:

Floor board features:

(1) Beautiful appearance, rich colors, flexible combination, can show different architectural styles.

(2) Lightweight (6~10 kg/m2), high strength (yield strength 250~550 MPa), excellent waterproof and shockproof.

(3) Convenient construction and installation, reducing installation, transportation workload and shortening the construction period.

(4) The raw steel sheet is part of the green building material and can be recycled.

(5) Excellent corrosion resistance and durability.