To satisfy the customers’ over-expected pleasure , we’ve our strong group to supply our greatest over-all provider which incorporates promoting, revenue, coming up with, output, quality managing, packing, warehousing and logistics for Chinese wholesale Color Steel Galvanized Metal Aluminum Ibr Trapezoidal Tile Sheet Roof Wall Panel Double Layer Cold Roll Forming Machine, We are going to continually strive to increase our company and supply the ideal quality products with aggressive price ranges. Any inquiry or comment is hugely appreciated. Remember to get hold of us freely.

To satisfy the customers’ over-expected pleasure , we’ve our strong group to supply our greatest over-all provider which incorporates promoting, revenue, coming up with, output, quality managing, packing, warehousing and logistics for Color Steel Ibr Trapezoidal Tile Sheet Roof Wall Panel Double Layer Cold Roll Forming Machine, Color Steel Roll Forming Machine, Double Layer Cold Roll Forming Machine, Corporate goal: Customers’ satisfaction is our goal, and sincerely hope to establish long-terms stable cooperative relations with customers to jointly develop the market. Building brilliant tomorrow together!Our company regards “reasonable prices, efficient production time and good after-sales service” as our tenet. We hope to cooperate with more customers for mutual development and benefits. We welcome potential buyers to contact us.

|

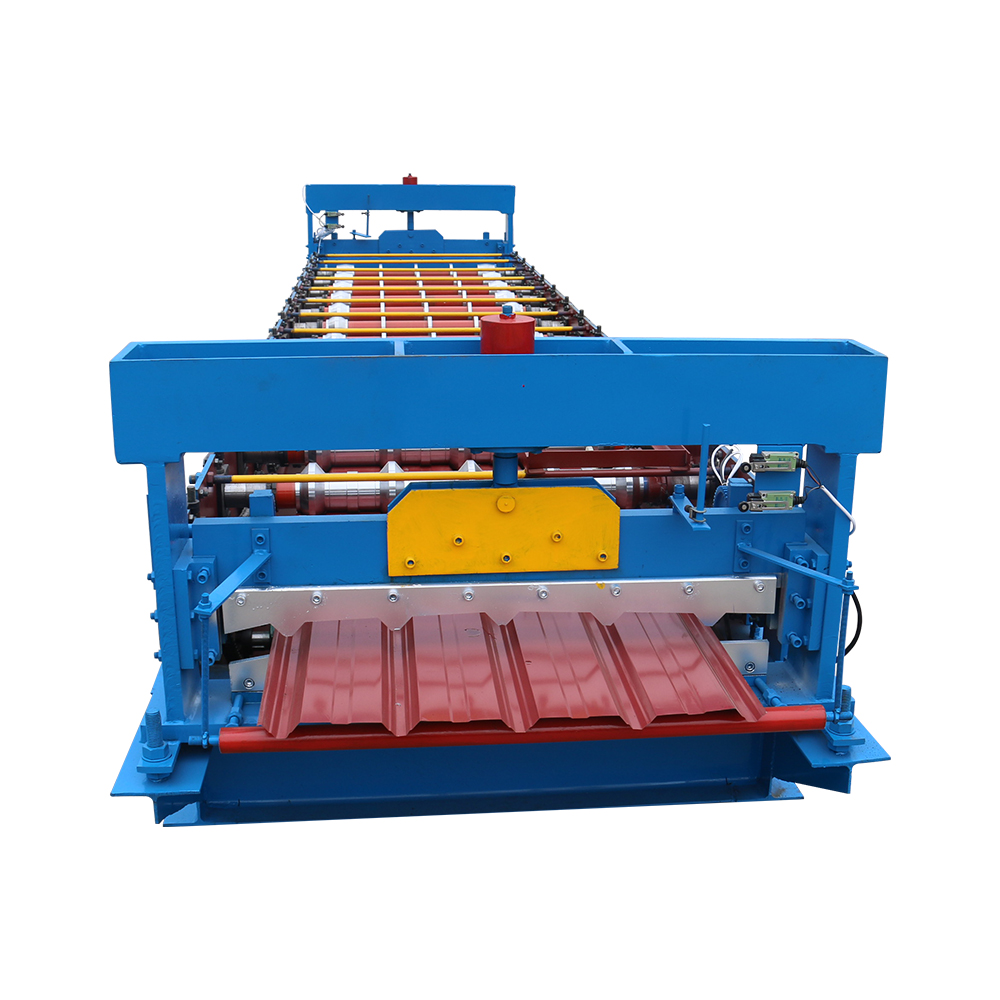

Trapezoidal roofing roll forming machine parameters |

||

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Machine picture display

Choose our machine and save your money from every part!

a. Low labor cost;

b. Convenient transportation;

c. Complete supporting industries.

FAQ

Q: What’s your strength comparing to the other supplier?

A: We’ll supplying you the best quality and service. We’ll give you good advise beyond your requirements. The lines are easily for installation and with low maintenance requirements.

Q: Can we be your agency abroad?

A: Surely if you have business for roll forming lines and we will welcome a lot for cooperating together.