We take pleasure in an extremely fantastic standing among our prospects for our great product top quality, competitive cost and the finest support for China Wholesale Roller Shutter Door Profile Roll Forming Machine Metal Garage Door Slats Making Machinery, Our goal is always to enable clients to comprehend their plans. We have been creating good endeavors to accomplish this win-win scenario and sincerely welcome you to join us.

We take pleasure in an extremely fantastic standing among our prospects for our great product top quality, competitive cost and the finest support for Door Profile Roll Forming Machine, Metal Garage Door Slats Making Machinery, Roller Shutter Door Profile Roll Forming Machine, As an experienced manufacturer we also accept customized order and we could make it the same as your picture or sample specification. The main goal of our company is to live a satisfactory memory to all the customers and establish a long term business relationship with buyers and users all over the world.

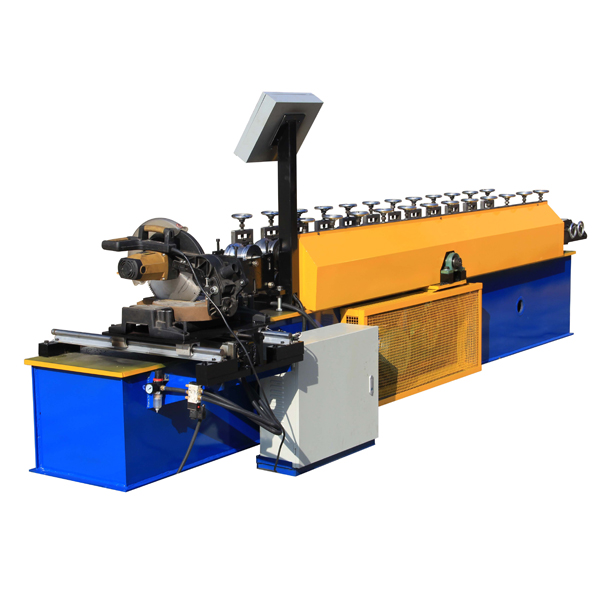

Machine parameters

|

Roller shutter door roll forming machine |

||

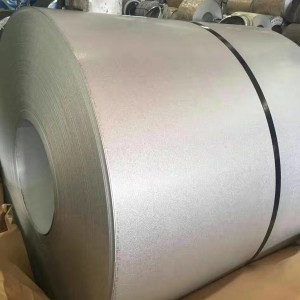

| 1 | Materials specification | Aluminum, galvalume, galvanized and pre-painted galvanized steel. |

| 2 | Thickness | 0.5mm to 1.0mm. |

| 3 | Main motor power | 4.5kw. |

| 4 | Hydraulic station power | 3kw. |

| 5 | Feeding width | Depends on the model of profile. |

| 6 | Yield stress | 235Mpa(33KSI) ~ 350Mpa |

| 7 | Roll forming speed | 12-15 m/minute. |

| 8 | Cutting tolerance | +/-2.5mm(length≤5000mm); +/-3.0mm(5000mm) |

| 9 | Manual uncoiled | Max. Capacity: 3000kgsManual decoiler |

| 10 | Coil inner diameter | 508mm/610mm |

| 11 | Voltage | 380v/50hz/3 phase |

| 12 | Numbers of stands | 12 stands/stations/pairs for each roll forming system |

| 13 | Roller material | High grade No.45 forged steel, coated with hard chrome. |

| 14 | Active shaft material | High grade No.45 carbon wrought steel, which can improve the integrated mechanic feature of the shaft. |

| 15 | Electric elements | PLC control panel, transducer imported from Mitsubishi of Japan.Other elements are from famous suppliers of China. |

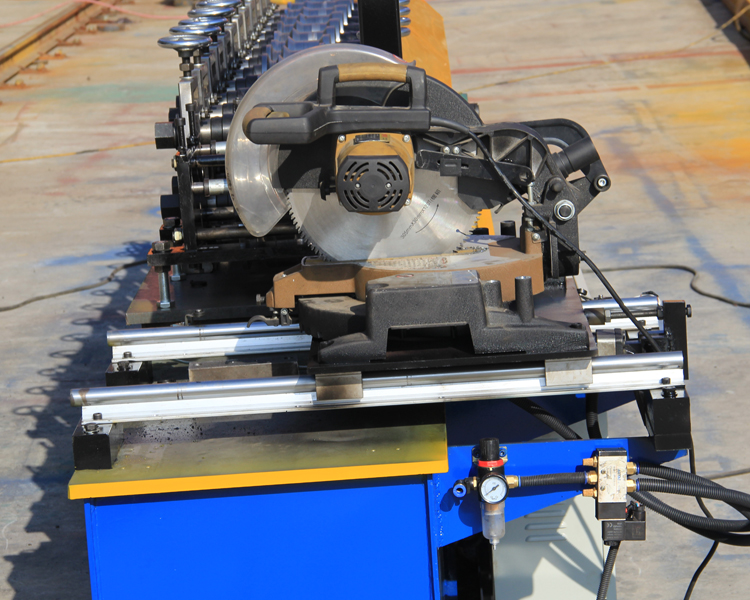

| 16 | Cutter blades | Cr12 mold steel with quenched treatment. |

Machine picture display

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Sales service:

1. We provide the technical support for whole life of our machines.

2. If buyers need the technician to go abroad , we will arrange the technician, but the buyers should take all the cost , including visa, round trip ticket etc.

-

Aluminum trapezoidal roof making machine

-

Aluminum Roofing Sheet Roll Forming Machine Dou...

-

Aluminized Galvanized Steel Coil

-

Aluminium plate bending machine

-

10 Ton Hydraulic Decoiler With Coil Car

-

Automatic Sheet Coil Slitting Machine

-

C Channel Roll Former Light Steel Keel Making M...

-

C Shape Purlin Roll Forming Machine