Fast and superior quotations, informed advisers to help you choose the correct solution that suits all your needs, a short generation time, responsible quality handle and unique products and services for paying and shipping affairs for China OEM Cnc Manual Sheet Bending Machine 80ton Hydraulic Press Brake Metal Bending Machine, To significantly increase our services high-quality, our business imports a large number of foreign advanced devices. Welcome clients from home and overseas to phone and inquire!

Fast and superior quotations, informed advisers to help you choose the correct solution that suits all your needs, a short generation time, responsible quality handle and unique products and services for paying and shipping affairs for Hydraulic Metal Bending Machine, Hydraulic Press Brake, Sheet Bending Machine, Our monthly output is more than 5000pcs. Now we have set up a strict quality control system. Please feel free to contact us for further information. We hope that we can establish long-term business relationships with you and carry out business on a mutually beneficial basis. We’ve been and will likely be always trying our best to serve you.

|

4 meters hydraulic roof sheet bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

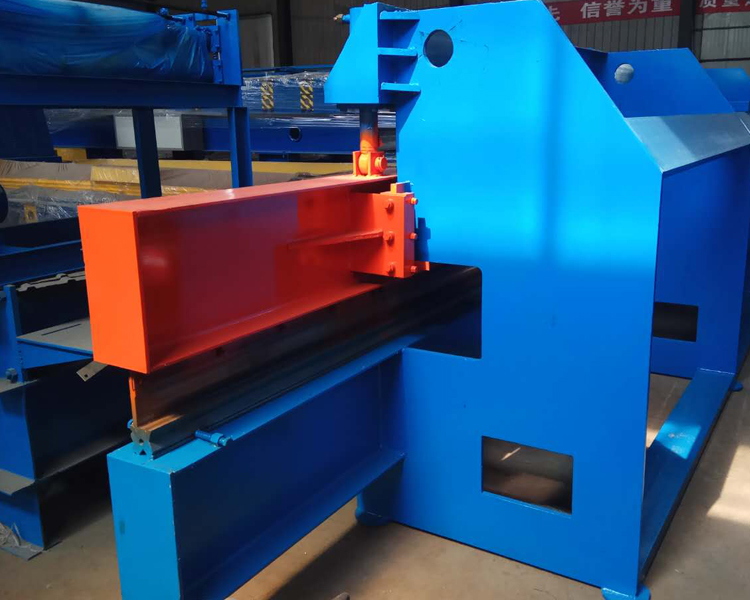

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

Short Lead Time for Omega Profile Roll Forming ...

-

Chinese Professional Steel Profile C U Omega Vi...

-

OEM/ODM China 910 Type Roof Use Automatic Singl...

-

China New Product Corrugated Asos Cement Sheet ...

-

Big discounting China CNC 4 Side Door Frame Edg...

-

Factory For Galvanized Steel Door Frame Roll Fo...