“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for China New Product Galvanized C Bracket C Purlin Roll Forming Making Machine Automatically Plc Control, Your aid is our everlasting power! Warmly welcome clients in your own home and abroad to go to our enterprise.

“Control the standard by the details, show the energy by quality”. Our business has strived to establish a really efficient and stable personnel team and explored an effective high quality manage process for C Bracket C Purlin Roll Forming Making Machine Distinguished Precise Criteria Speed Economic Panel, C Bracket C Purlin Roll Forming Making Machine Structural Steel C Purlin U Purlin U Shape Decorative Panel L Shape, C Bracket Roll Forming Making Machine Speed Made Cold Roll Former Passed Ce And Iso Construction Building Material, We have been making our products for more than 20 years . Mainly do wholesale , so we have the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we provide good products , but also because of our good after-sale service . We are here waiting for you for your inquiry.

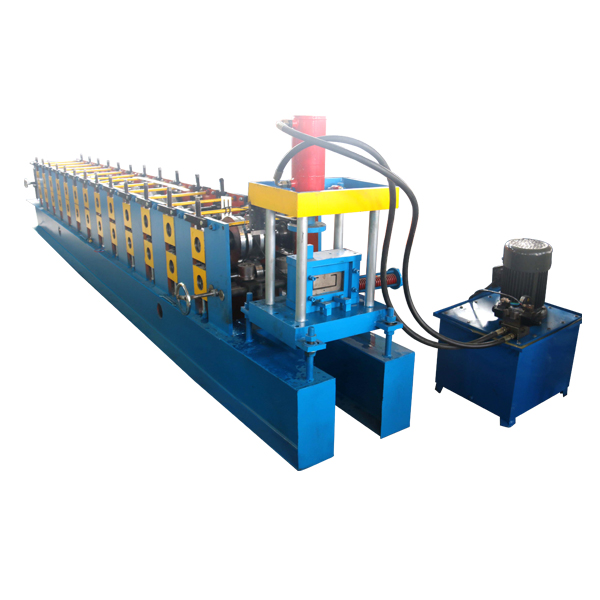

C Shape Purlin Roll Forming Machine parts: single-end feeding machine, feeding leveling, forming system, straightening mechanism, at single + double holes, after forming shear system, supporting material platform.

| Purlin roll forming machine technical parameters | ||

| 1 | Suitable to process | Steel plate |

| 2 | Rollers | 12 rows |

| 3 | Dimensions | 11*1.3*1.5m |

| 4 | Power | 11.5kw+7.5kw |

| 5 | Thickness of the plate | 1-3mm |

| 6 | Productivity | 8-10m/min |

| 7 | Middle plate thickness | 20mm |

| 8 | Driving ways | 2.6-inch China wheels and link chain |

| 9 | Diameter and material of the forming axis | 80mm |

| 10 | Weight | About 8.5T |

| 11 | Voltage | 380V 50HZ3 phase |

| 12 | Roll material | GCr15(bearing steel)hard chrome plated after heat treatment |

| 13 | Shaft material | 40Cr Modulation of heat treatment after polishing hard chromium plating |

| 14 | On both sides of the wall material | A3 steel |

| 15 | Frame | International H-beam |

| 16 | Blade material | Cr12Mov |

| 17 | Forming wheel | Bearing steel quenching |

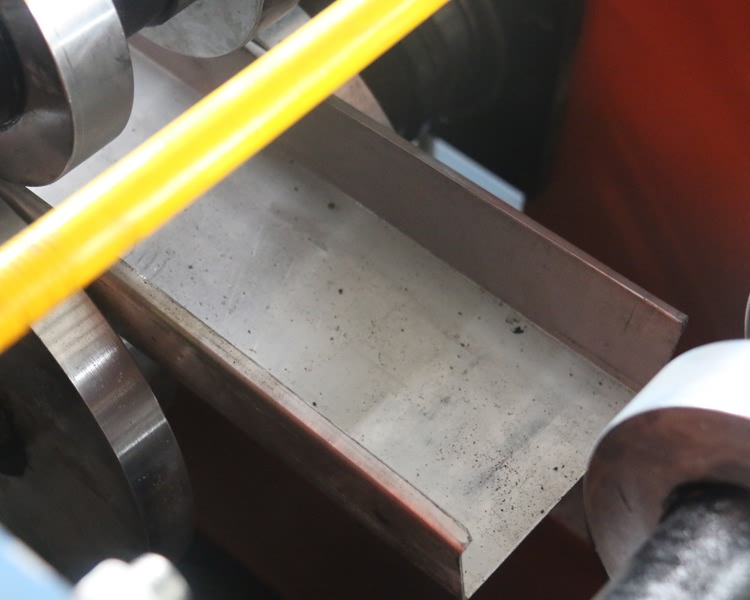

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery)

Company profile:

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

-

Wholesale OEM Electromagnetic Manual Box Foldin...

-

factory low price Hot Sale Glazed Tile Mobile R...

-

Short Lead Time for Modern Design Promotional M...

-

China Cheap price Hot Sell New Purlin Roof Shee...

-

New Fashion Design for Eps Granules Chinses Eps...

-

Fast delivery Steel Light Gauge Roll Forming Ma...