It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We’re hunting forward to your check out for joint development for China Gold Supplier for China Roof Corrugated Sheet Metal Roof Making Machine, Welcomes all abroad close friends and retailers to ascertain collaboration with us. We are going to give you with genuine, high-quality and successful company to satisfy your requirements.

It really is our obligation to satisfy your requirements and efficiently serve you. Your fulfillment is our greatest reward. We’re hunting forward to your check out for joint development for China Synthetic Resin Tile Machine, Plastic Sheet Profile Machine, We solution have passed through the national skilled certification and been well received in our key industry. Our professional engineering team will often be ready to serve you for consultation and feedback. We have been able to also provide you with no cost samples to meet your needs. Best efforts might be produced to provide you the very best service and solutions. For anyone who is considering our business and solutions, be sure to speak to us by sending us emails or get in touch with us right away. As a way to know our solutions and enterprise. lot more, you’ll be able to come to our factory to find out it. We will constantly welcome guests from around the globe to our firm. o build enterprise. elations with us. You should definitely feel absolutely free to make contact with us for small business and we believe we are going to share the top trading practical experience with all our merchants.

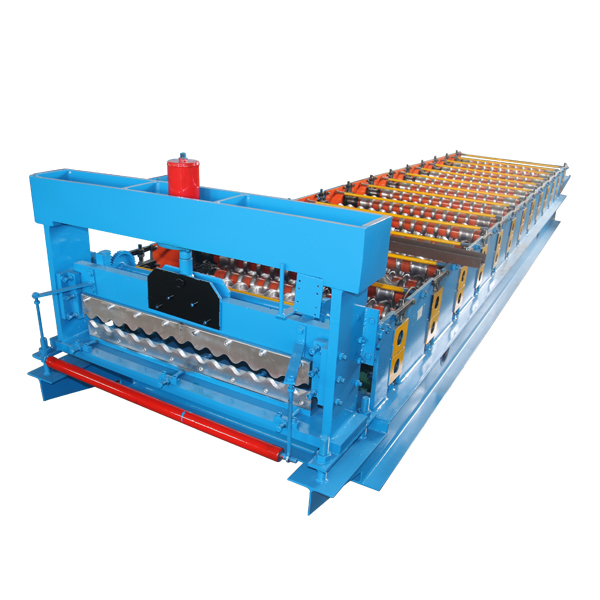

Parameters of corrugated metal roofing sheet machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Photos:

If you have any questions about the model, parameters, etc., please feel free to contact us. We will do our best to answer your questions and look forward to cooperation.