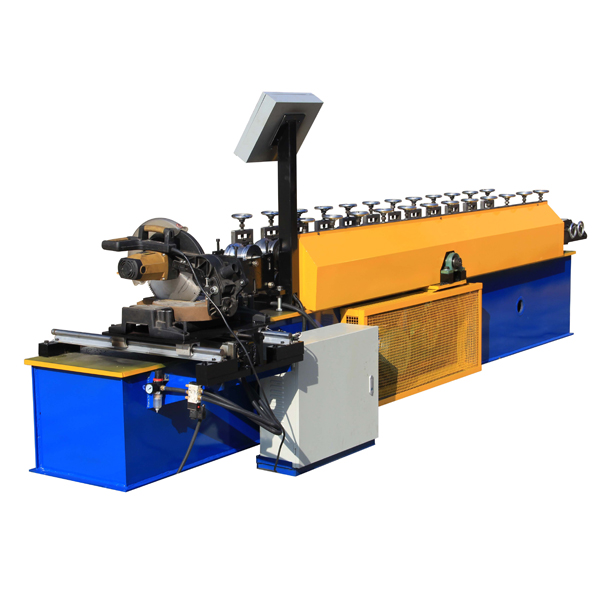

Cheapest Price Corrugated Roof Panels Fabrication Machine - Glazed roll forming machine manufacturers – Haixing Industrial Detail:

Glazed roll forming machine manufacturers parameters

| 1 | Main motor power | 4kW, 3 phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Main frame | 300/350 mm H-beam |

| 7 | Backboard thickness | 16 mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0-15/ min |

| 12 | Roll station | 13 roll steps (according to different design) |

| 13 | Roller diameter | 70 mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12 |

| 16 | Cr-plating size | 0.05 mm |

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

Machine packaging and shipping details

Standard export packaging: 1 * 40 GP container.

The main machine is bare and fixed in the container with wire.

The rollers is oiled and packaged in plastic film.

Electronic equipment is packed in wooden cases.

Product detail pictures:

Related Product Guide:

Gorgeous condominium in Hopedale – News – MetroWest Daily News, Framingham, MA | Roof Sheet Curving Machine

Top 10 Superyachts At The Fort Lauderdale International Boat Show | Ibr Roof Sheet Making Machine

Cheapest Price Corrugated Roof Panels Fabrication Machine - Glazed roll forming machine manufacturers – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Best quality Ceiling Tile T Bar T Grid System M...

-

China Cheap price C And U Purlin Machine - Roo...

-

China wholesale Highway Guardrail Metal Machine...

-

Reasonable price for Roofing Roll Forming Machi...

-

Best quality Sheet Metal Roofing Machine - C Z...

-

Big discounting Steel C Z U Purlin Roll Forming...