Cheap price T Keel Roll Forming Machine - OEM Factory for Automatic Colorful Aluminium Section Tile Manufacturing Equipment Roof Wall Panel Double Layer Roll Forming Machinery – Haixing Industrial Detail:

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for OEM Factory for Automatic Colorful Aluminium Section Tile Manufacturing Equipment Roof Wall Panel Double Layer Roll Forming Machinery, We cordially welcome consumers from at your home and abroad to affix us and cooperate with us to take pleasure in a greater long term.

Our objective is to present premium quality products at aggressive prices, and top-notch services to buyers around the world. We have been ISO9001, CE, and GS certified and strictly adhere to their excellent specifications for Aluminium Section Manufacturing Machinery, Roof Tile Manufacturing Equipment, Roof Wall Panel Double Layer Roll Forming Machine, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, make sure you kindly contact us, we’ve been looking forward to building up a great business relationship with you.

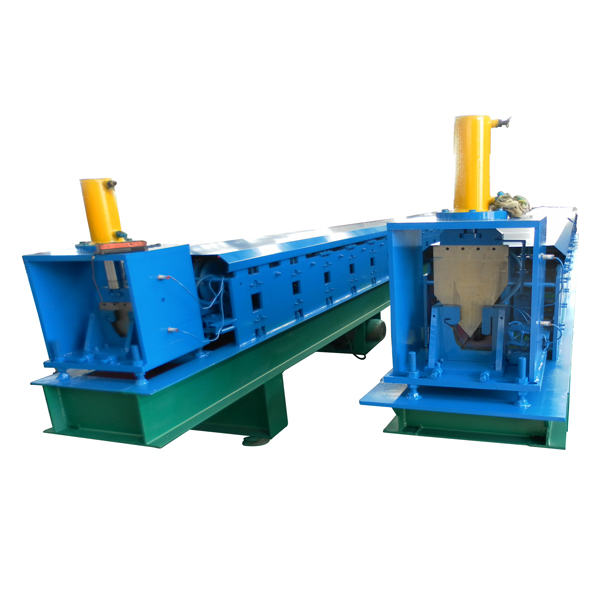

This roof roll forming machine can press both glazed and trapezoidal tiles.

Parameters of steel double layer roll forming machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

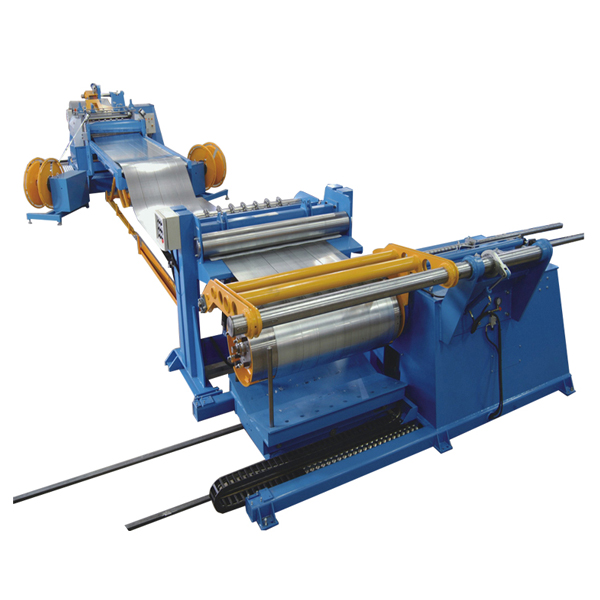

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 840mm, 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

We are committed to research and develop this industry for more than 20 years, and our productions are widely used in gardens, factories, resorts, hotels, exhibition halls, vacation lands, ancient architectures and modern villas.

Q:Are you a manufacturer?

A:Yes absolutely. Welcome a lot for your visiting to us.

Q:What’s the delivery time?

Abnormally will take 60 days, for small lines will take 30 days.

Q:Do you have after-sale support?

A:Yes, we’re always here for giving you advice and support for technical details since we have senior technician.

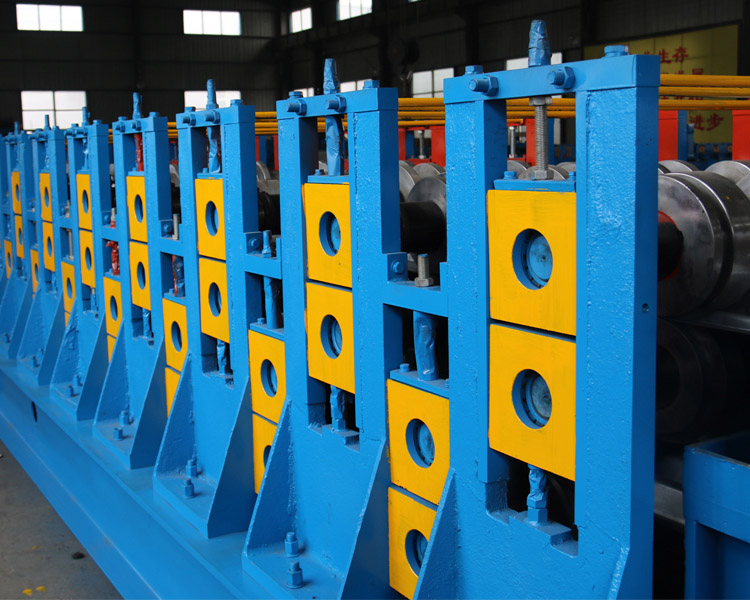

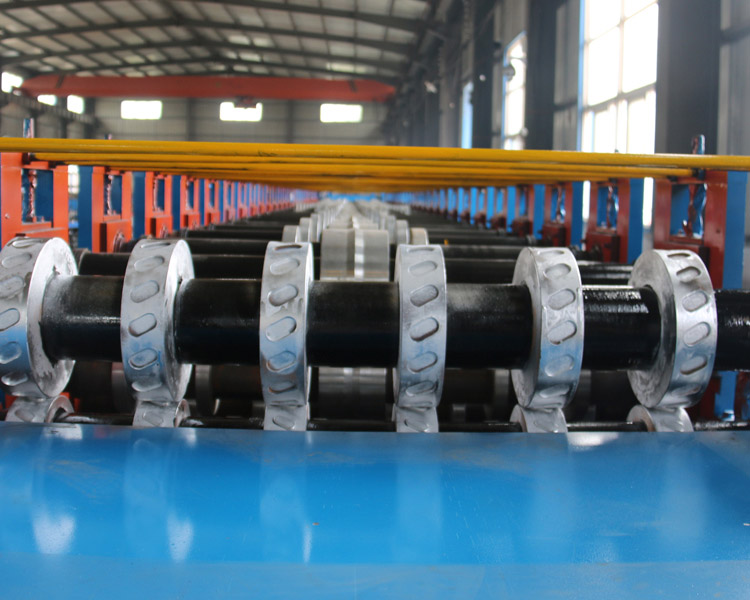

Product detail pictures:

Related Product Guide:

VIDEO VAULT | How to catch a cheater at a Vegas casino | Floor Deck Macking Machine

A city made of cardboard in an art gallery | Roof Sheet Curving Machine

Cheap price T Keel Roll Forming Machine - OEM Factory for Automatic Colorful Aluminium Section Tile Manufacturing Equipment Roof Wall Panel Double Layer Roll Forming Machinery – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

Factory Price For Roof Corrugated Sheet Making ...

-

Factory Price Light Weight Steel Roll Former -...

-

OEM Manufacturer Decoiler Straightener Machine ...

-

Hot Selling for Curved Color Steel Roof Tile -...

-

2017 wholesale price Shear Machine - Aluminum ...

-

China New Product Used Slitting Line - Floor D...