We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for Cheap price Steel Structure Cold Purlin Roll C Z Purling Forming Machine, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

We goal to understand excellent disfigurement from the manufacturing and supply the top support to domestic and abroad clients wholeheartedly for C Channel Forming Machine, C Shape Forming Machine, Cold Purlin Roll C Z Purling Forming Machine, We’ll supply much better solutions with diversified designs and expert services. We sincerely welcome friends from over the world to visit our company and cooperate with us on the basis of long-term and mutual benefits.

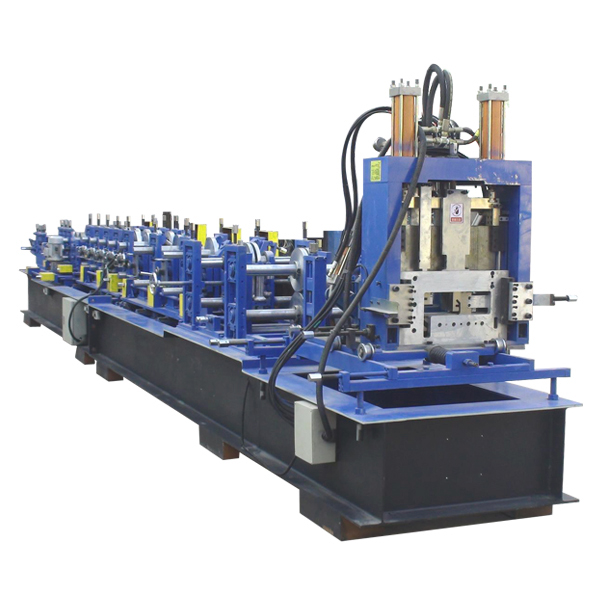

Automatic CZ interchange purlin machine process flow:

Manual decoiler– punching hole– roll forming machine– molding press– PLC control box– hydraulic system– post cut– output table.

|

Purlin roll forming machine |

||

| 1 | Suitable to process | Steel plate |

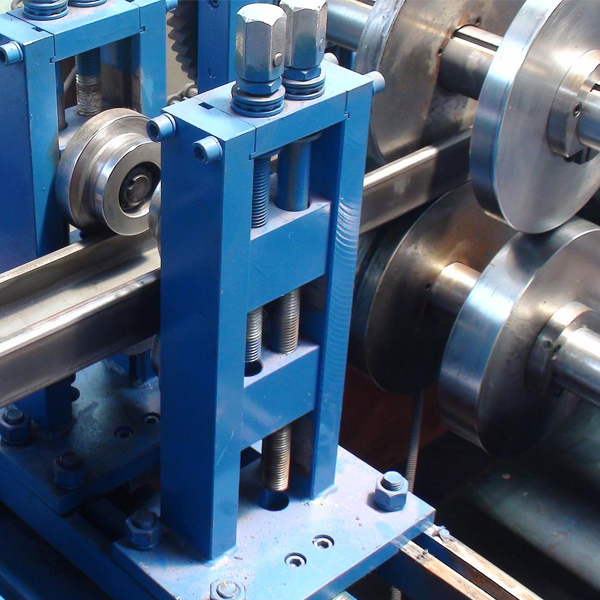

| 2 | Rollers | 18 rows(Before and after the leveling and contains no lead to send passes) |

| 3 | Dimensions | 11*1.3*1.5m |

| 4 | Power | 11.5kw+7.5kw |

| 5 | Thickness of the plate | 1-3mm |

| 6 | Productivity | 8-10m/min |

| 7 | Middle plate thickness | 20mm |

| 8 | Driving ways | 2.6-inch China wheels and link chain |

| 9 | Diameter and material of the forming axis | 80mm |

| 10 | Weight | About 8.5T |

| 11 | Voltage | 380V 50HZ3 phase |

| 12 | Roll material | GCr15(bearing steel)hard chrome plated after heat treatment |

| 13 | Shaft material | 40Cr Modulation of heat treatment after polishing hard chromium plating |

| 14 | On both sides of the wall material | A3 steel |

| 15 | Frame | International H-beam |

| 16 | Blade material | Cr12Mov |

| 17 | Forming wheel | Bearing steel quenching |

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m)

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit

2. Package: export standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after inspect the machine before delivery)

Advantages of our roll forming machines

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.

-

Wholesale OEM/ODM China High Quality Roof Panel...

-

Steel Roof Tiles R Panel Cold Roll Forming Machine

-

Factory made hot-sale Automatic Tile Cutting Ma...

-

factory Outlets for New Technology Machine Shee...

-

Discountable price Wall Panel Thickness 14mm Ro...

-

Cheap price Metal Roofing Galvanized Aluminum C...