Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for Cheap price 2018 New Roof Use Double Layer Corrugated Profile Steel Roofing Sheet Roll Forming Machine Roof Tile Making Machine, If possible, please send your requirements with a detailed list including the style/item and quantity you require. We will then send our best prices to you.

Our goal is usually to consolidate and improve the high quality and service of existing solutions, meanwhile continuously create new items to meet unique customers’ requires for Aluminium Roofing Sheet Making Machine, Metal Roofing Roll Forming Machine, Portable Metal Roofing Roll Forming Machine, Welcome to visit our company, factory and our showroom where displays various hair items that will meet your expectation. Meanwhile, it is convenient to visit our website, and our sales staff will try their best to offer you the best service. Make sure you contact us if you want more information. Our aim is to help customers realize their goals. We are making great efforts to achieve this win-win situation.

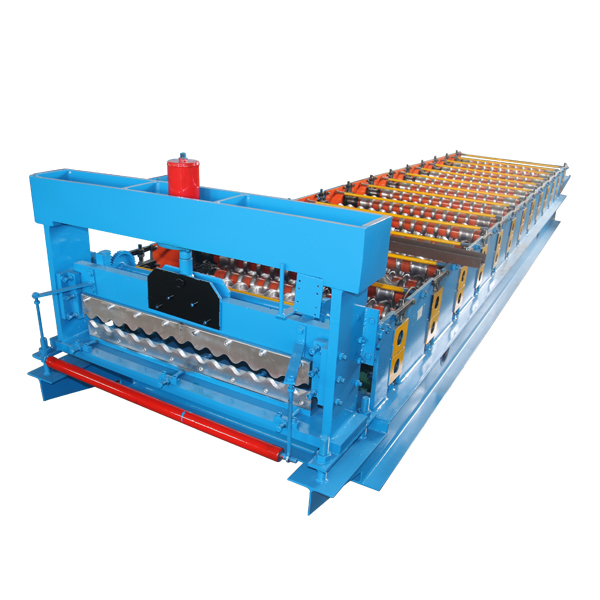

Parameters of corrugated metal roofing sheet machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

Components:

Manual un-coiler: 1 set

Guiding platform: 1 set

Coil strip leveler: 1 set

Main machine of roll forming: 1 set

Electric-motor: 1 set

Cutting device: 1 set

Hydraulic station: 1 set

PLC control: 1 set

Supporter table: 1 set

Photos:

If you have any questions about the model, parameters, etc., please feel free to contact us. We will do our best to answer your questions and look forward to cooperation.

-

factory Outlets for s Making Building Material ...

-

Online Exporter Double Layer Roofing Sheet Roll...

-

ODM Supplier Automatic Steel Slitting Line Roll...

-

Steel Roof Tiles R Panel Cold Roll Forming Machine

-

2019 New Style Automatic Stud And Track Light K...

-

Factory Promotional Automatic Metal Colored Roo...