The light keel roll forming machine can produce a variety of lightweight keels, and the keel produced has an aesthetic appearance.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

After Service

a. One year guarantee for whole machine.

b. 24 hours technical support by email or calling

c. If there is any problem found of the machine, we will repair it for free in one year.

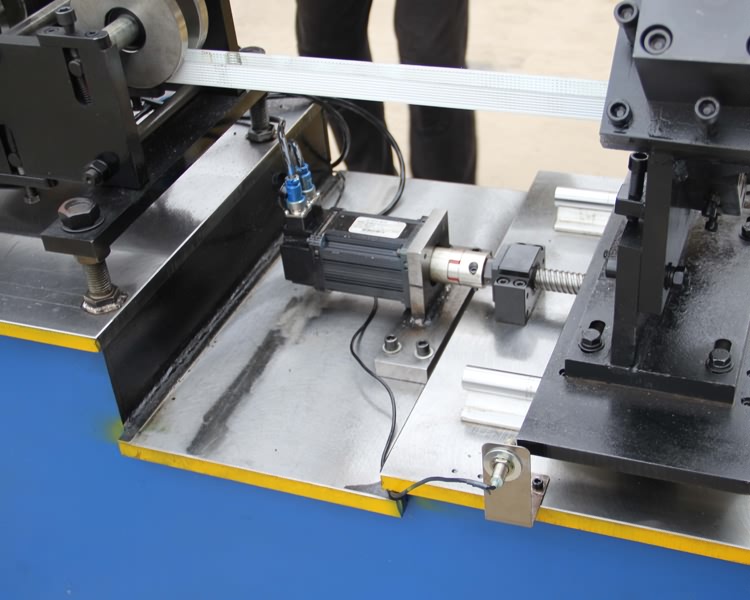

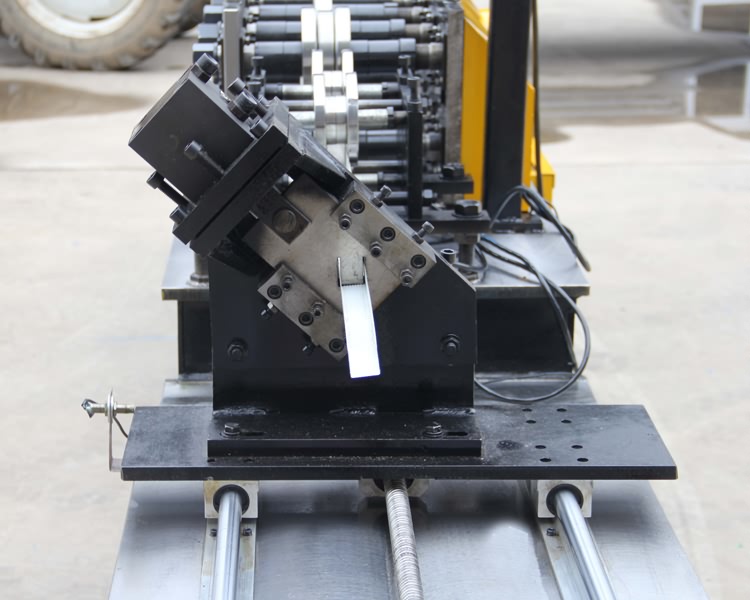

Ceiling U Profiles Roll Forming Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Installation and training:

a. If buyers visit our factory and check the machine, we will teach you how to install and use the machine, and also train your workers/technician face to face.

b. Without visiting, we will send you user manual and video to teach you to install and operate.

c. If buyer needs our technician to go to your local factory, please arrange board and lodging and other necessary things.