C Channel Roll Former Light Steel Keel Making Machine

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

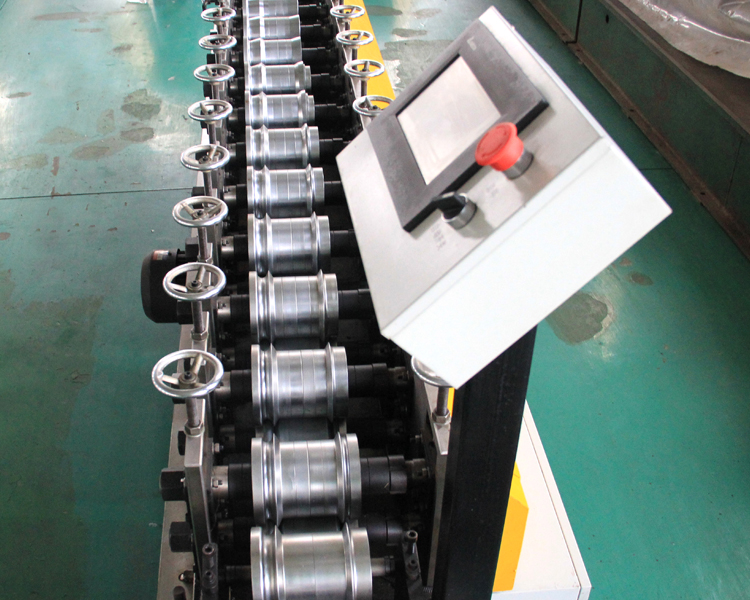

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

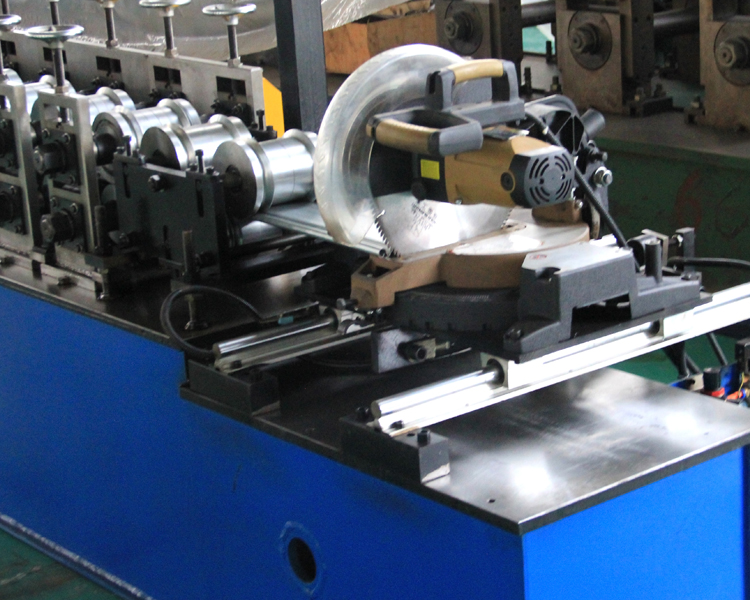

Ceiling c channel making machine picture display

C Channel Roll Former Light Steel Keel Making Machine packaging:

The main unit is bare, fixed in the container with wire, the drum is oiled, and packed in plastic film. The control box is equipped with a carton.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Advantages of our roll forming machines:

1, Our machine can use galvanized steel, color steel plate or aluminum plate as material board.

2, Using computer control, PLC display. Therefore the machine is easy to operate, stable and reliable operation, durable, maintenance-free.

3. We can manufacture and design various roll forming machines according to customer requirements.