Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for Bottom price R Panel U Panel Corrugated Panel Curving Machine Roll Forming Machine, We welcome customers, business associations and friends from all parts of the world to contact us and seek cooperation for mutual benefits.

Our primary goal is always to offer you our customers a serious and responsible company relationship, providing personalized attention to all of them for Corrugated Panel Curving Machine Roll Forming Machine, Urving Machine Roll Forming Machine, Used Metal Sheet Rolling Machine, Relying on superior quality and excellent post-sales, our solutions sell well in America, Europe, the Middle East and South Africa. We have been also the appointed OEM factory for several worlds’ famous products and solutions brands. Welcome to contact us for further negotiation and cooperation.

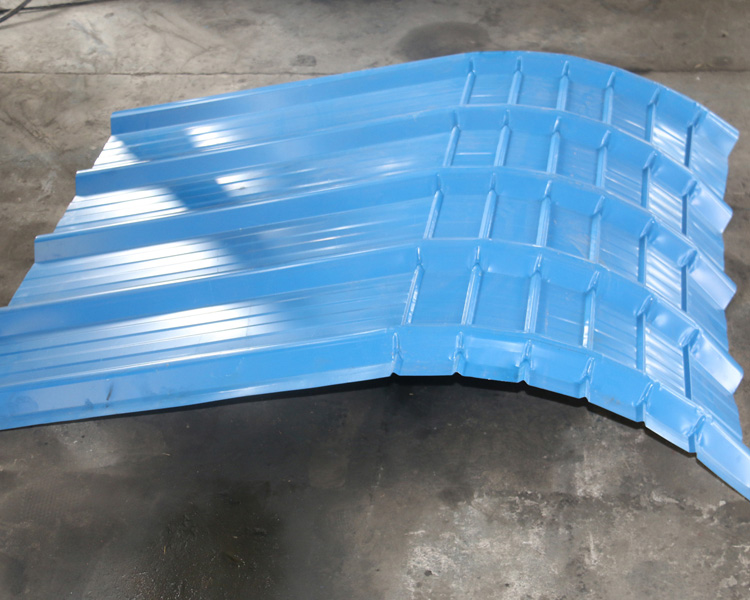

Application of Curved Roof Panel Roll Forming Machine

For architecture: making roof panel, wall panel, ceiling panel, etc.

For Industry: making refrigerating room panel, automobile panel, electric appliance housing, etc.

|

Curved Roof Panel Roll Forming Machine parameters |

||

| 1 | Main motor power | 5.5kw, 3 phase or as your request |

| 2 | Hydraulic motor power | 4kw |

| 3 | Hydraulic Pressure | 10-12MPa |

| 4 | Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| 5 | Control System | PLC Delta Inverter |

| 6 | Main Frame | 300mm/350mm H-Beam or 350mm |

| 7 | Backboard Thickness | 16mm |

| 8 | Chain Size | 1 Inch |

| 9 | Feeding Material | color steel coils |

| 10 | Feeding Thickness | 0.3-0.8mm |

| 11 | Feeding Width | 100-1200mm |

| 12 | Effective width | 840-1050mm |

| 13 | Productivity | 0-15/min |

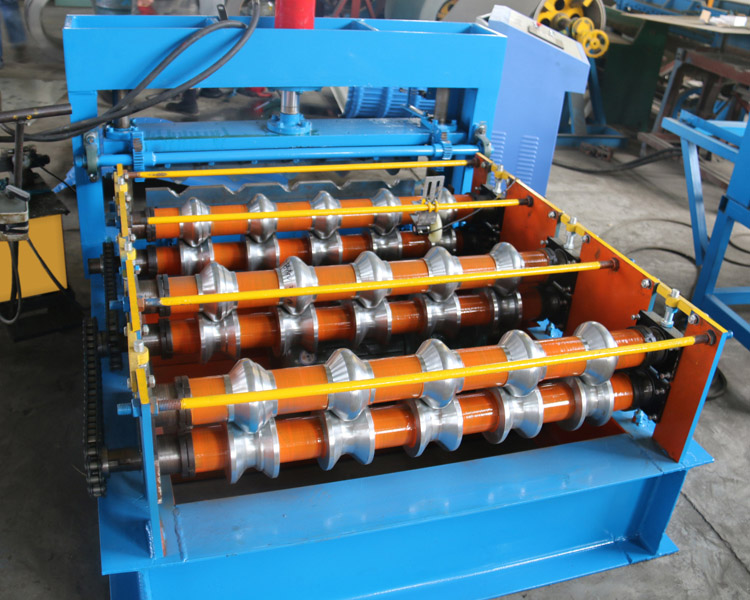

| 14 | Roll Station | 13 roll steps(according to different design) |

| 15 | Roller Diameter | 70mm(depend on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating Size | 0.05mm |

| 19 | Overall Size | 6800*1400*1150mm |

| 20 | Total Weight | 5.8T |

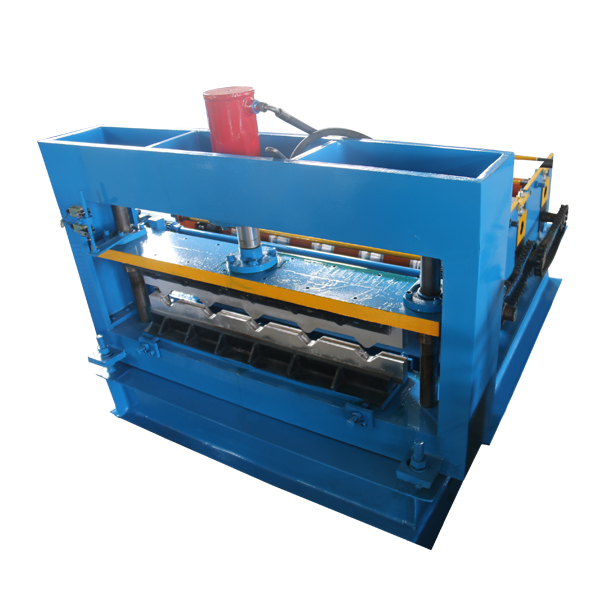

Machine Photos:

Package and shipment details:

1. Main roll forming machine package by plastic film

2. Main machine spare parts package by paper box

3. We have a professional technician load to ensure that the goods are loaded into the container without any damage.

4. Transportation: machines need one 20 feet container to hold.

5. Please provide us the nearest port name, we will ask shipping cost and arrange shipping for you.

-

Factory For Metal Drywall Tracks Studs Color St...

-

China Factory for Colorful Stone Coated Metal R...

-

Fast delivery Corrugated Iron Roof Sheet Making...

-

Good User Reputation for Portable Metal Corruga...

-

Rapid Delivery for Ibr Metal Roof Sheet Tile Ma...

-

Best Price on Modern Design Promotional Metal D...