Being a result of ours specialty and service consciousness, our corporation has won a very good status amid buyers all over the world for Bottom price Galvanized Steel Sheet Profile Metal Roofing Corrugated Roll Forming Machines, Your inquiry will be highly welcomed and a win-win prosperous development are what we are expecting.

Being a result of ours specialty and service consciousness, our corporation has won a very good status amid buyers all over the world for Corrguated Sheet Metal Panel Making Machine, Corrugated Roll Forming Machines, Metal Roofing Corrugated Roll Forming Machines, Honest to every customers are our requested! First-class serve, best quality, best price and fastest delivery date is our advantage! Give every customers good serve is our tenet! This makes our company get the favour of customers and support! Welcome all over the world customers send us enquiry and looking forward your good co-operation !Remember to your inquiry for more details or request for dealership in selected regions.

Metal Roofing Galvanized Aluminum Corrugated Steel Sheet Making Machine parameters:

| 1 | Main motor power | 4kW, 3 phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/ 3 phase/ 50 Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Main frame | 300/350 mm H-beam |

| 7 | Backboard thickness | 16 mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8 mm |

| 11 | Productivity | 0-15/ min |

| 12 | Roll station | 13 roll steps (according to different design) |

| 13 | Roller diameter | 70 mm (depends on different design) |

| 14 | Roller material | 45# steel |

| 15 | Cutter material | Cr12 |

| 16 | Cr-plating size | 0.05 mm |

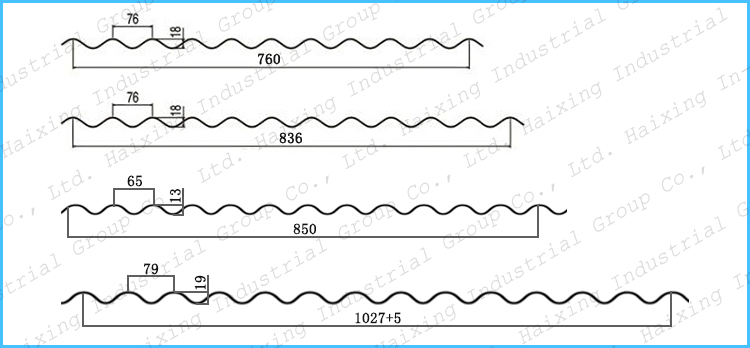

Popular drawing of corrugated roof metal sheets:

762 drawing, 850 drawing, 836 drawing, 1032 drawing

Our Advantage:

1. Our machine motor is GERMAN BRAND SEMENS;

2. Our roller spacer is 4 mm thick seamless steel pipe;

3. Our output table can adjust the height according to customer demands;

4. Our PLC control console can look around 360 degrees;

5. All easy-broken pars can be changed within 14 months in free.

Easy-broken parts:

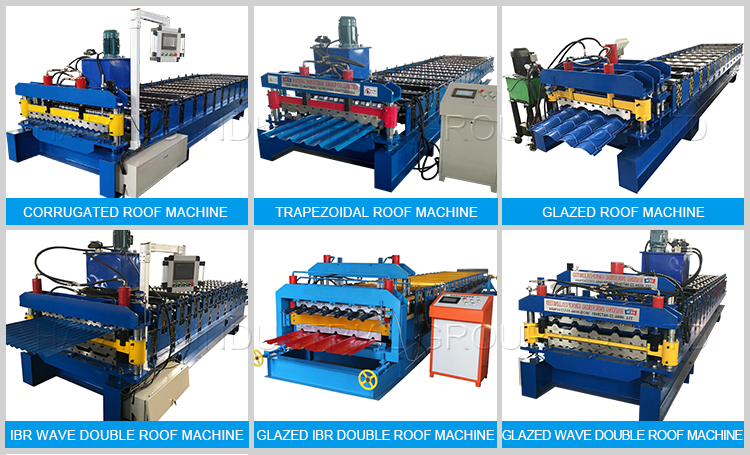

Other relative roof roll forming machine:

Our company other products:

Packaging Details:

1. The main machine is covered by the plastic film.

2. PLC control box, spare parts, and other small parts are packed by wooden carton box.

Sales Service:

1. We provide the technical support for the whole life of our roof roll forming machines.

2. If buyers need the technician to go abroad, we will arrange the technician, but the buyers should take all the cost, including visa, round trip ticket, etc.

-

Cheapest Factory Fast Changed Size Cz Section P...

-

OEM/ODM Supplier Automatic Steel Coil Decoiling...

-

High Quality Galvanized Steel Profile Metal Cor...

-

Quoted price for Hot Coil Stretch Precision Lev...

-

Big discounting stone coated metal roofing tile...

-

China Factory for Wc67y-160t/3200 Hydraulic She...