We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Bottom price Colorful Stone Coated Metal Roof Tile Machine For Manufacturing Ceramic Tile Plate, We, with great passion and faithfulness, are ready to give you with best companies and striding ahead with you to create a vibrant foreseeable future.

We constantly believe that one’s character decides products’ high quality, the details decides products’ high-quality ,together with the REALISTIC,EFFICIENT AND INNOVATIVE crew spirit for Colorful Stone Coated Metal Roof Tile Machine, Machines For Manufacturing Ceramic Tile Plate, Standing Seam Metal Roof Machine, Our solutions have national accreditation standards for experienced, premium quality items, affordable value, was welcomed by people around the globe. Our goods will continue to increase in the order and look forward to cooperation with you, Really should any of those products be of interest to you, please letus know. We are going to be pleased to give you a quotation up on receipt of one’s detailed specifications.

Our Steel Colored Stone Coated Production Line meets the diverse requirements of our customers.

The Steel Colored Stone Coated Production Line is described in detail as follows:

NO. 1 Auto bottom glue spraying section

| Appearance size | 4000*1000*2000mm |

| Driving section | 3KW Excitation motor or frequency speed regulation (AS per customers’ requirements) |

| Automatic pressure spray tank | 1set; Capability:200kg; Range:0.6~1Mpa |

| Automatic glue machine motor | Servo motor; Power:750w; PLC |

| Automatic spray gun | 4 set (spare parts) |

| Dust collecting fan | 1 set; Power: 200w |

| Damp proof lamp | 1 pcs; Power: 100w |

| Conveying device | Chain reciprocating |

| Air compressor | 1 set; Power: 7.5kw |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Agitator | 1 set; Power: 1.5kw |

NO. 2 Auto stone coated section

| Appearance size | 3500*1000*1500mm |

| Framework | Steel welding |

| Conveying device | Chain reciprocating |

| Automatic sand hopper | 1 set; Capability: 200kg |

| Bucket lift | 1 set |

| Manual sandblast gun | 4 sets |

NO. 3 The first time drying section

| Appearance size | 25000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

NO. 4 Auto face glue spraying section

| Appearance size | 3000*1000*2000mm |

| Framework | Steel welding |

| Damp proof lamp | 1 pcs; Power:100w |

| Automatic pressure spray tank | 1 set; Capability: 200kg; Range: 0.6~1Mpa |

| Conveying device | Chain reciprocating |

| Automatic spray gun | 4 sets (spare parts) |

| Manual patch glue gun | 4 sets |

| Dust control of axial flow fan | 1 set; Power: 200w |

| Automatic glue machine motor | Servo motor; Power: 750w |

NO. 5 The second time drying section

| Appearance size | 30000*1000*1200mm |

| Framework | Steel welding |

| Frame type thermal insulation wall | 1.2mm cold steel with Rock wool |

| Automatic temperature controller | 4 sets; Range: 0°~160° |

| Infrared heating tube | 30pcs; Power: 30kw |

| Conveying device | Chain reciprocating |

| Air cooling device | 1 set; Power: 200w |

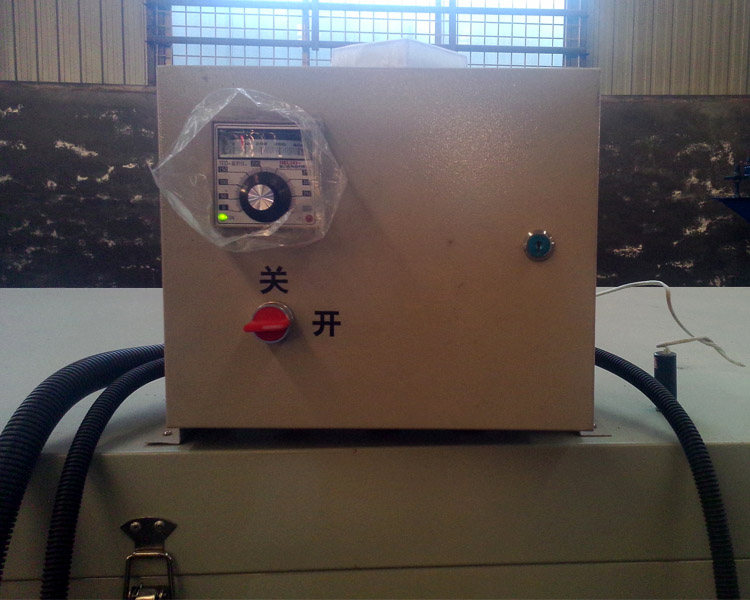

Machine Photos:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Factory Directly supply China Double Layer Roll...

-

Factory Selling Steel Coil Automatic Slitting M...

-

Wholesale Price 6 Ton Color Steel Coils Manual ...

-

Factory wholesale China Construction Purlin Bra...

-

China New Product Furring Channel Ceiling Keel ...

-

Newly Arrival Garage Door Machine Shutter Door ...