Big Discount Steel Door Roller Shutter Cold Roll Forming Machine - Rock Wool Sandwich Sheet Production Line – Haixing Industrial Detail:

|

Rock Wool Sandwich Sheet Production Line parameters |

||

|

1 |

Equipment overall dimensions |

30m*2.6m*3m |

|

2 |

Total weight |

About 16 ton |

|

3 |

Control system |

Omron encoder PLC |

|

4 |

Main motor power |

Planetary cycloid reducer, 4kw, 380V, 50HZ |

|

5 |

Processing speed |

4~4.5 m/min, continuous stepless adjusted, variable frequency speed regulation, digital display |

|

6 |

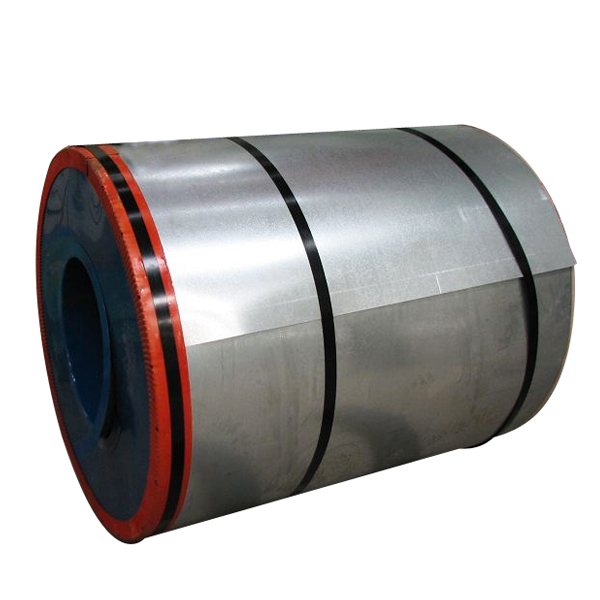

raw material |

1.2 meters |

|

7 |

Voltage |

380V |

|

8 |

Roller material |

chrome plated on 45# steel forgings |

|

9 |

Number of rubber shafts |

27 foams, 39 rock wool |

|

10 |

Total power |

30 kw |

|

11 |

Synchronous controller |

Digital synchronous controller |

|

12 |

Corrugated press motor power |

Double-stage cycloid reducer 4kw, 380V, 50HZ |

|

13 |

Application |

roof panel, wall panel |

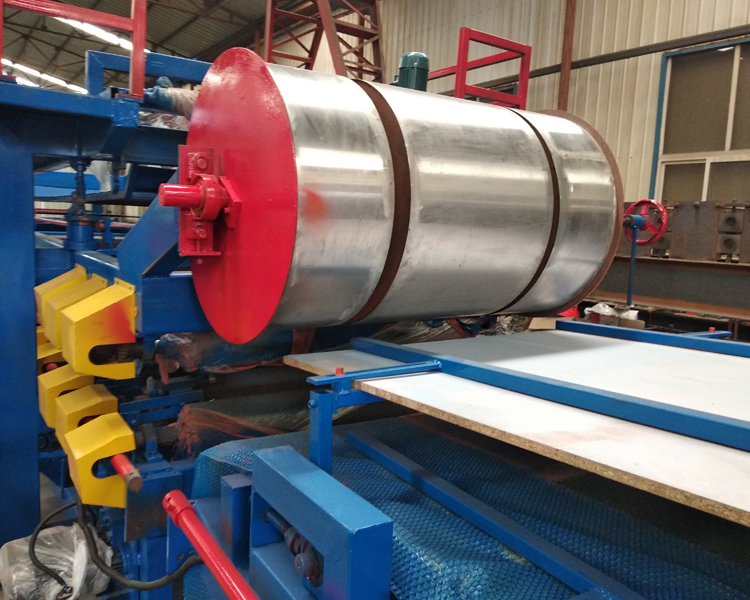

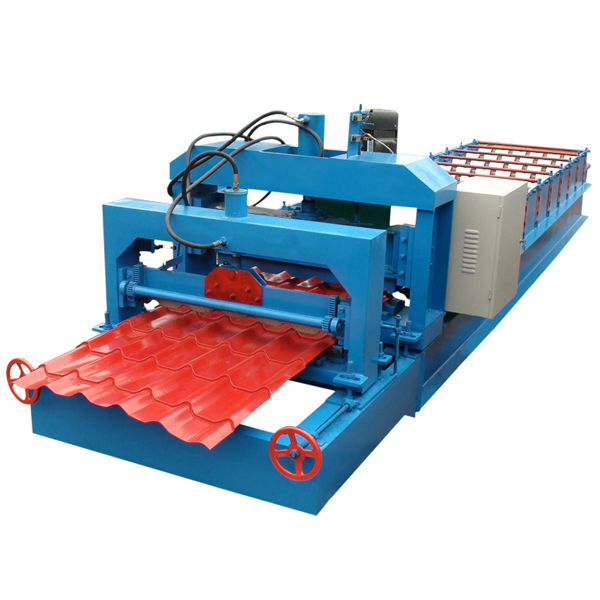

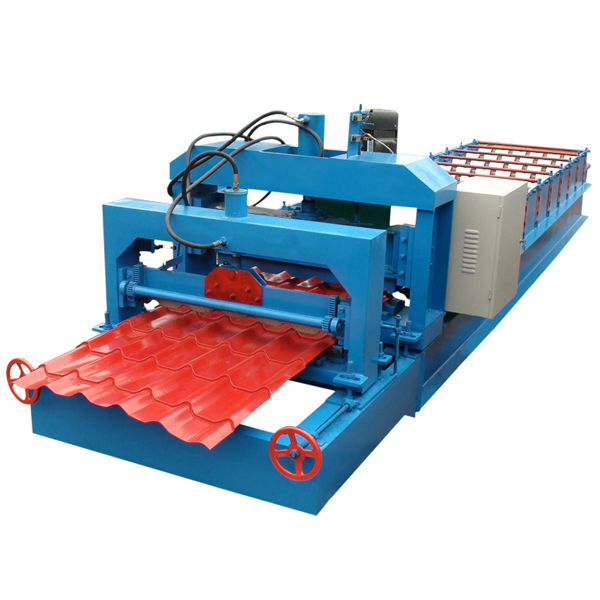

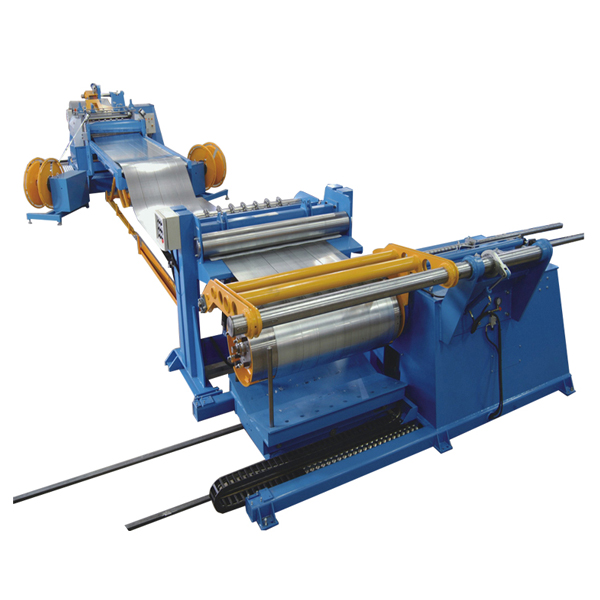

Components of rock wool sandwich sheet production line:

|

Roll forming machine |

1 set |

|

Hydraulic cutter |

1 set |

|

Electrical control system |

1 set |

|

Hydraulic system |

1 set |

|

Normal stacker table |

3 PC. 1m*1m |

|

Manual decoiler |

1 set. Maximum load: 5T. |

Machine picture display

Roof advantages:

Waterproof, fireproof, antifreeze, corrosion resistant, compressive strength, light weight, beautiful, and environmentally friendly.

Product detail pictures:

Related Product Guide:

Would you spend £230 on a face mask for your bottom? | Roof Sheet Curving Machine

Design integrating copper cladding | Steel Downpipe Roll Forming Machine

Big Discount Steel Door Roller Shutter Cold Roll Forming Machine - Rock Wool Sandwich Sheet Production Line – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

2017 Good Quality Sandwich Panel Machine Turkey...

-

Wholesale Price Double Layle Metal Tile Making ...

-

Hot New Products Used Gutter Machine - Steel d...

-

Special Price for Used Manual Metal Bending Mac...

-

OEM/ODM Factory Arched Roof Tile Making Machine...

-

Factory source Rain Channel Making Machine - S...