We not only will try our greatest to offer you outstanding products and services to every single buyer, but also are ready to receive any suggestion offered by our buyers for Best-Selling Trade Assurance Steel Decking Floor Machinery For Sale Ceramic Floor Tile Manufacturing Machine, We welcome new and aged buyers from all walks of daily life to get hold of us for upcoming business enterprise interactions and acquiring mutual good results!

We not only will try our greatest to offer you outstanding products and services to every single buyer, but also are ready to receive any suggestion offered by our buyers for Floor Decking Rolling Mill Machine, Galvanized Steel Sheet Forming Machine Forming Russia Type Floor Decking Panels, Trade Assurance Steel Decking Floor Machinery For Sale Ceramic Floor Tile Manufacturing Machine, With its rich manufacturing experience, high-quality items, and perfect after-sale service, the company has gained good reputation and has become one of the famous enterprise specialized in manufacturing series.We sincerely hope to establish business relation with you and pursue mutual benefit.

|

Automatic metal floor deck roll forming machine parameters |

||

|

Feeding platform |

1 | Frame structure: steel plate welded |

| 2 | roller flatting system and pre-hand cutting system | |

| 3 | Advantage: not scratch the surface of metal plate | |

|

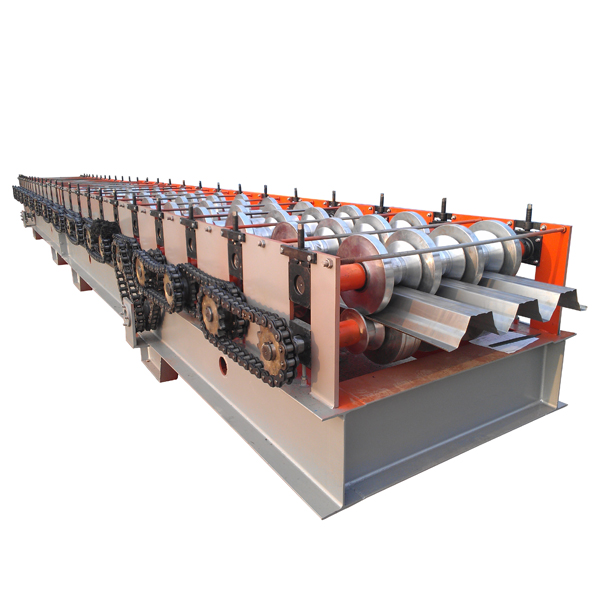

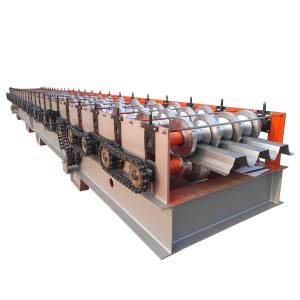

Roll forming M/C |

1 | Machine weight: 13 tons |

| 2 | Installation dimensions: 1500*1800*1500mm | |

| 3 | Machine under frame: steel 400 H-beam | |

| 4 | Sidewall: 45# steel plates | |

| 5 | Roller stations: 28 rows | |

| 6 | Shaft diameter: 85mm | |

| 7 | Side wall plate: 24mm | |

| 8 | Main shaft material: 45# steel with finish turning | |

| 9 | Roller material: 45# forging steel with chromium plate | |

| 10 | Chromium plate thickness: 0.05mm | |

| 11 | Motor power: 15kW*2, brand Siemens | |

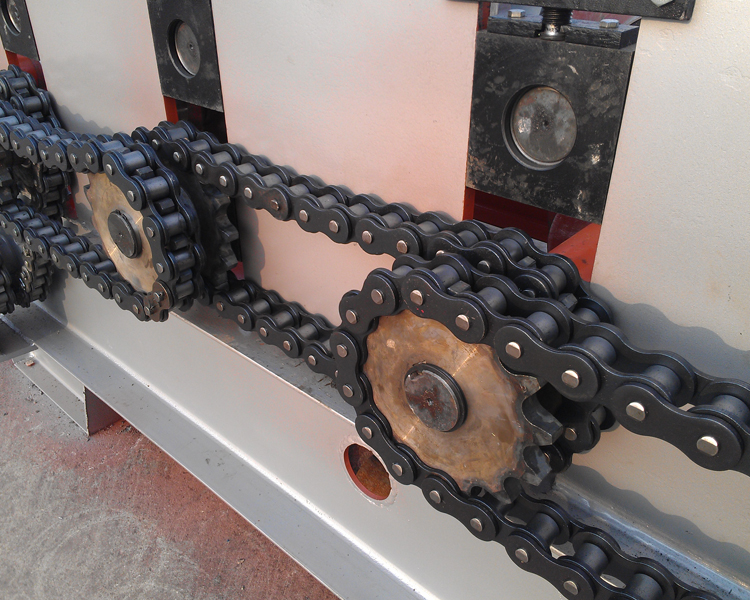

| 12 | Reducer type: 2-8# gear speed reducer-Shanghai, China | |

| 13 | Chain wheel and cycle chain: 1.2-inch | |

| 14 | Production line speed: 10-12m/minutes | |

|

PLC control system |

1 |

Functions: adapts quantity cutting system, length of roof sheet can be set on the computer |

| 2 | Tolerance: within 1.0mm | |

| 3 |

Frequency converter: Delta |

|

| 4 |

PLC is Siemens |

|

| 5 |

Encoder: Omron |

|

| 6 |

Touchscreen: Delta |

|

| 7 |

Voltage standard: 3 phases 380V/50Hz or according to customer’s need |

|

| 8 |

Pressing die material: Cr12 |

|

|

Hydraulic pressing device |

1 |

Quenched treatment 58 to 62ºC |

| 2 |

Length tolerance: ±2mm |

|

| 3 |

Pump station motor: 5.5kW, LICHAO, Shanghai |

|

| 4 |

Hydraulic oil: 40# |

|

|

Hydraulic cutting device |

1 |

Functions: adapts electric drive and automatic location system to decide the dimension and cut the target |

| 2 |

Working method: stop to post then post to cut |

|

| 3 |

Cutting mold material: Cr12 |

|

| 4 |

Quenched treatment 58 to 62°C |

|

| 5 |

Length tolerance: ±2mm |

|

| 6 |

Pump station motor: 5.5kW, LICHAO, Shanghai |

|

Machine photos

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

-

ODM Manufacturer Trade Assurance Stone Coated R...

-

China OEM China Nigeria Used Corrugated Roll Fo...

-

Personlized Products Special Multi-function Pro...

-

OEM/ODM China Hydraulic Steel Coil Decoiler For...

-

High reputation LD-1300A BOPP self adhesive tap...

-

Chinese Professional 2016 New Roof Use Double L...