Best-Selling Floor Deck Panel Roll Forming Machine - Online Exporter C Channel Roof Light Keel Forming Machine Manufactory Roll Forming Machine – Haixing Industrial Detail:

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for Online Exporter C Channel Roof Light Keel Forming Machine Manufactory Roll Forming Machine, We welcome new and previous clients from all walks of lifestyle to get in touch with us for long term business relationships and mutual accomplishment!

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for C Channel Roof Truss, C Shape Forming Machine, Metal Stud Making Machine, Our qualified engineering team will usually be prepared to serve you for consultation and feedback. We’re able to also deliver you with absolutely free samples to meet your needs. Best efforts might be made to offer you the ideal service and goods. For anyone who is interested in our company and goods, please make contact with us by sending us emails or contact us right away. In order to know our solutions and organization. ar more, you can come to our factory to determine it. We have been going to usually welcome guests from around the globe to our corporation. o create small business relations with us. Please genuinely feel no cost to speak to us for enterprise. nd we believe we have been intending to share the most effective trading practical experience with all our merchants.

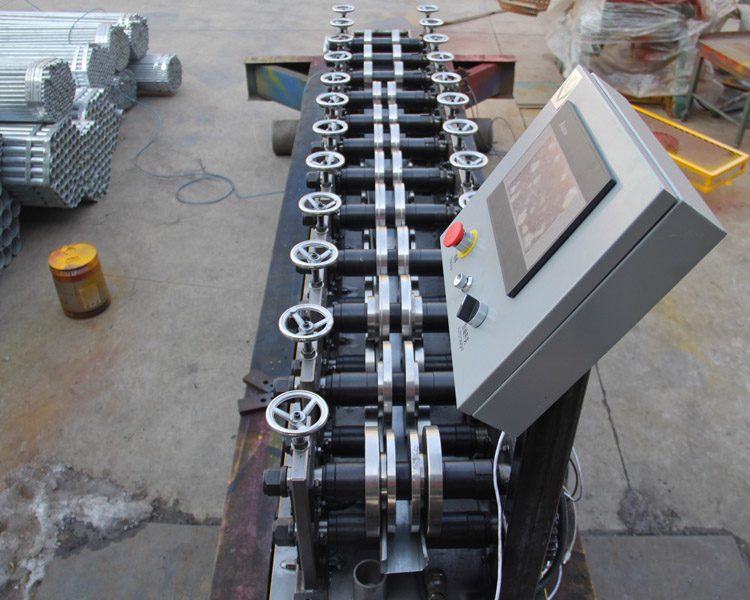

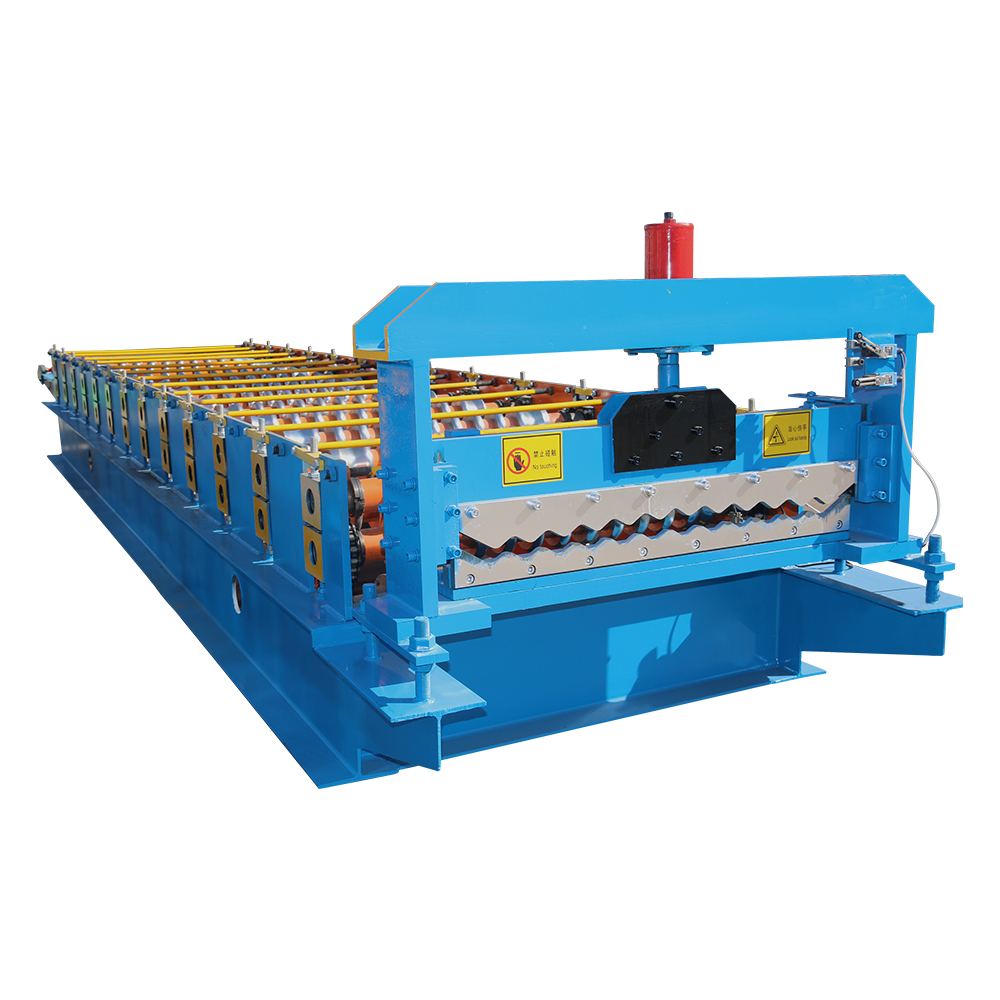

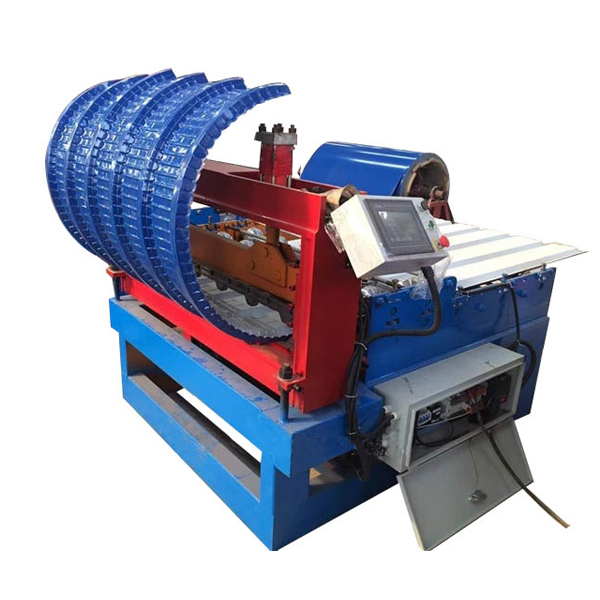

Equipment components of C channel light steel keel making machine:

Manual decoiling, roll forming machine, computer control system, hydraulic control system, cutting, run out table.

|

Light steel keel roll forming machine parameters |

||

| 1 | Main motor power | 4kw/3 phase (or as your request) |

| 2 | Hydraulic motor power | 3kw |

| 3 | Hydraulic pressure | 10~12MPa |

| 4 | Voltage | 380V/3 phase/50HZ (or as your request) |

| 5 | Control System | PLC Delta /Panasonic/Siemens/ |

| 6 | Main Frame | 300/350mm H-Beam |

| 7 | Backboard Thickness | 17/20mm |

| 8 | Chain size | 1/2inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.18~0.8mm |

| 11 | Feeding width | Better as your profile or from our design |

| 12 | Effective width | Better as your profile or from our design |

| 13 | Productivity | 0-3min |

| 14 | Roll station | 11~20 roll steps(according to different design) |

| 15 | Roller diameter | 75mm (according to different design) |

| 16 | Roller material | 45#steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-Plating size | 0.05mm |

| 19 | Overall size | 5000mm*1000mm*1500mm |

| 20 | Total weight | 2~12T |

C channel light steel keel roll forming machine picture display

Packaging Details:

1. Machine is covered by plastic film

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Terms:

1. Delivery: within 60 days after receiving the deposit.

2. Package: export standard package for container.

3. Payment: TT (30% by TT in advance, 70% by TT after inspect the machine before delivery).

Product detail pictures:

Related Product Guide:

Facebook is hosting an online abuse summit with other tech leaders Engadget Engadget save share save share save share save share save share save share ear icon eye icon text file vr | Ibr Roof Sheet Making Machine

The Top Yachts at the Fort Lauderdale International Boat Show | Floor Deck Macking Machine

Best-Selling Floor Deck Panel Roll Forming Machine - Online Exporter C Channel Roof Light Keel Forming Machine Manufactory Roll Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

OEM/ODM Supplier Small Sheet Bending Machine -...

-

Good User Reputation for Roof Ridge Making Mach...

-

Low price for Big Structure Roof Steel Machine ...

-

Factory supplied Stud Track Roll Forming Machin...

-

Popular Design for Hydraulic Uncoiler - Roof r...

-

Popular Design for Glazed Roof Sheet - Roof Pa...