By using a sound small business credit, excellent after-sales provider and modern producing facilities, now we have earned an exceptional track record between our clients across the whole world for Best quality Manufacture Sells Dw89nc Hydraulic Semi Automatic Tube Bending Machine, We look forward to providing you with our goods while in the in close proximity to long term, and you will discover our quotation is extremely realistic as well as high-quality of our solutions is incredibly outstanding!

By using a sound small business credit, excellent after-sales provider and modern producing facilities, now we have earned an exceptional track record between our clients across the whole world for Bender, Bending, Tube Bending Machine, The development of our company not only needs the guarantee of quality, reasonable price and perfect service, but also relies on our customer’s trust and support! In the future, we are going to continue with the most qualified and high quality service to offer the most competitive price, Together with our customers and achieve win-win! Welcome to inquiry and consult!

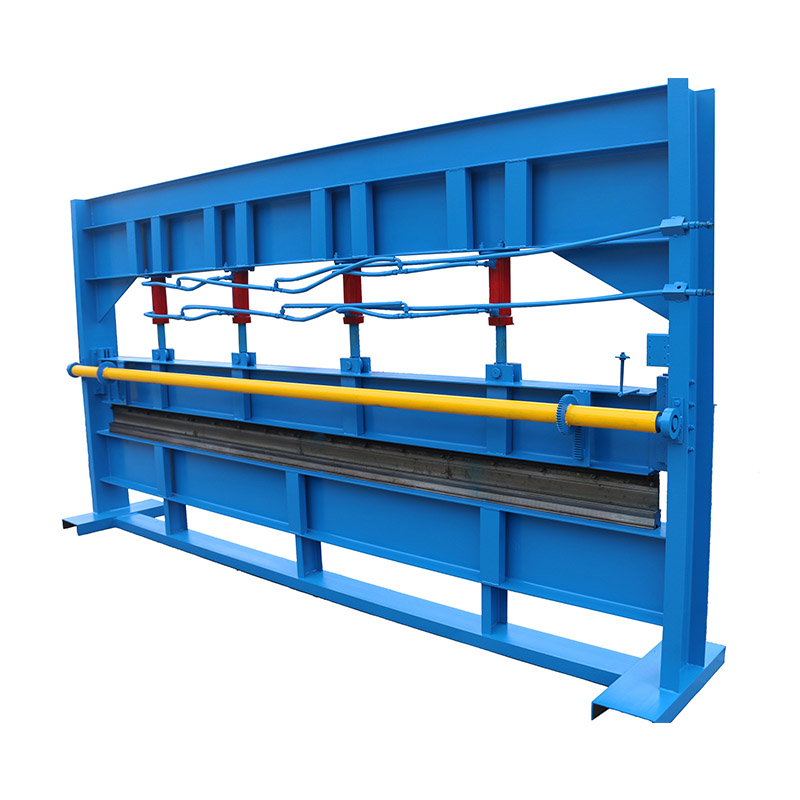

Functions and Characteristics

1. Steel- welded construction, standard upper and lower dies,vibration to eliminate inner stress,hydraulic transmission system,foot pedal with emergency stop.with high strength and good rigidity.

2. Hydraulic top-drive, steadiness and reliability. Mechanical stop, steel torsion bar to maintain synchronization, with high precision.

3. Motorized-adjusting device for back gauge and ram’s stroke, DRO for back gauge and ram stroke.

4. Deflection compensation unit installed under the worktable.

5. Manual crowned lower die holder is adopted for the machine above 250 tons.

6. DRO to display the values of back gauge and ram stroke.

|

Sheet metal bending machine parameters |

||

|

1 |

Cutting &Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V/3phase/50 HZ(or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor+ Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic PLC |

|

8 |

Bending degree |

0-90 |

|

9 |

Operating mode |

Button+ Mitsubishi |

|

10 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

11 |

Backboard Thickness |

17mm |

|

12 |

Feeding Material |

GI/PPGI/PPGL |

|

14 |

Feeding Thickness |

0.2-0.8mm |

|

15 |

Feeding Width |

1-4m |

|

16 |

Effective width |

1-4mm |

|

17 |

Productivity |

0-60times/min |

|

20 |

Roller material |

45# steel |

|

21 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC = 60-62 degrees |

|

22 |

Brand Square |

A3 35mm thick plate arch |

|

22 |

Cr-Plating Size |

0.05mm |

|

23 |

Overall Size |

4300*1200*2100mm |

|

24 |

Total Weight |

1.8T |

Machine photos

Sales service:

1. We provide technical support for the entire life of the machine.

2. If the buyer needs a technician to go abroad, we will arrange the technicians, but the buyer should bear all the expenses, including visas, round-trip tickets, etc.

-

Professional Factory for China Ibr Hot Sale Ful...

-

OEM Customized Metal Stud C U Channel Profile S...

-

2019 Good Quality 10mm Automatic Cnc Hydraulic ...

-

China Wholesale Top Famous Brand Digital Contro...

-

Low price for Steel Coil Automated Decoiler Wor...

-

Manufacturer of Metal Glazed Tile Roof Tile Mak...