All we do is often involved with our tenet ” Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Best Price on Color Steel Galvanized Metal Trapezoidal Roof Tile Sheet Roll Forming Machine, Thanks for taking your worthwhile time to visit us and sit up for have a nice cooperation along with you.

All we do is often involved with our tenet ” Purchaser to start with, Rely on initially, devoting over the food stuff packaging and environmental defense for Color Steel Galvanized Machine, Roof Sheet Roll Forming Machine, Trapezoidal Roof Machine, We honor ourselves as a company that comprises of a strong team of professionals who are innovative and well experienced in the international trading, business development and product advancement. Moreover, the company stays unique among its competitors due to its superior standard of quality in production, and its efficiency and flexibility in business support.

Our advantages

We are professional! Our factory has extensive experience in product and export processes. We have an ultra-low price advantage! Our factory helps you save money from many details:

1, lower labor costs

2, convenient transportation

3, perfect supporting industry

Our machine is the best machine: PLC uses well-known brands to ensure high precision and easy operation.

Our machines are fully automatic: you only need to enter the length of the steel plate and the required number of pieces, the machine will run automatically.

Color Steel Roof Sheet Roll Forming Machine Technical parameters:

|

1 |

Cutting & Hydraulic type |

Double guide pillar |

|

2 |

Hydraulic motor power |

3kw or 4kw |

|

3 |

Hydraulic Pressure |

10-12MPa |

|

4 |

Voltage |

380V /3phase/ 50 HZ (or as your requirement) |

|

5 |

Cutting drive |

Decelerating motor + Chain drive gear all by high-frequency |

|

6 |

Control System |

Panasonic /Siemens / Schneider / Delta PLC |

|

7 |

Length measurement |

Encoder |

|

8 |

Main Frame |

300mm/350mm H-Beam or 350mm |

|

9 |

Backboard Thickness |

17mm/200mm |

|

10 |

Chain Size |

1inch/2inch |

|

11 |

Feeding Material |

As your drawing or from our designer |

|

12 |

Feeding Thickness |

0.18mm-0.8mm |

|

13 |

Effective width |

As your drawing or from our designer |

|

14 |

Productivity |

10-15/min |

|

15 |

Roll Station |

From11 rows (according to different design) |

|

16 |

Roller Diameter |

70mm/75mm (depend on different design) |

|

17 |

Roller material |

45# steel |

|

18 |

Cutter material |

Cr12 mould steel heat-treated hardness of HRC 60-62 degrees |

|

19 |

Total Weight |

3t-12t |

|

20 |

Package of machine |

Waterproofing membrane, standard export packing |

|

Color Steel Roof Sheet Roll Forming Machine technical parameters can be changed, according to customer’s need. |

||

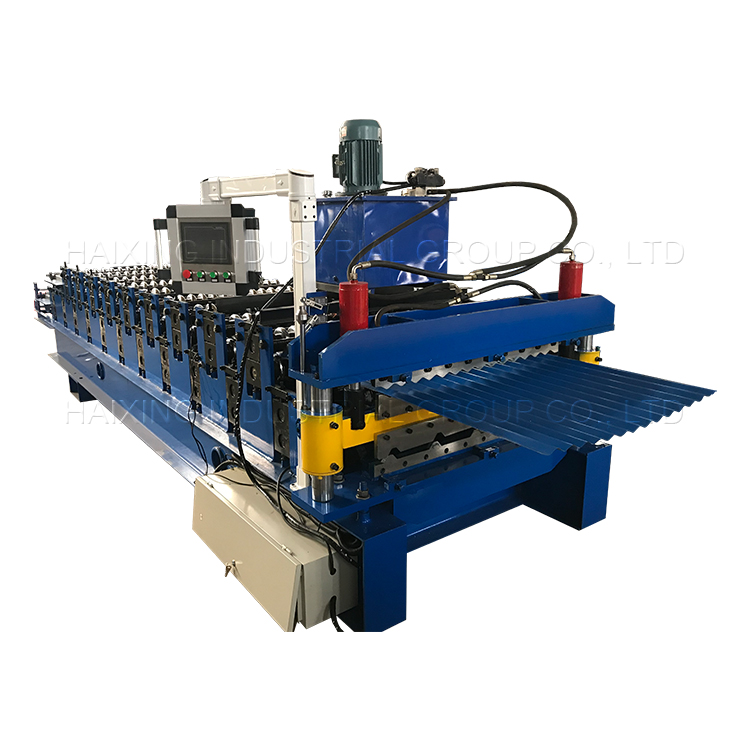

Components of Color Steel Roof Sheet Roll Forming Machine

Manual decoiler——————-1 set(5t)

Guiding Platform——————1 set

Coil Strip Leveler—————–1 set

Main Machine of Roll Forming—-1 set

Hydraulic Station—————- -1 set

Supporter Table——————-1 set

Coil Strip Leveler——————1 set

Picture showing

Tianjin Haixing Import & Export Co., Ltd. specializes in producing all kinds of roofing machines, roofing panels of various sizes, PPGI/ GI, aluminum-zinc steel coils, galvanized steel coils, galvanized steel sheets, galvanized steel coils /sheets.

Our first priority is quality improvement and customer satisfaction.

High-quality products, professional services, and preferential prices welcome every customer to visit and purchase!!! We will provide you with 24-hour service, please feel free to contact us if necessary.

-

China Supplier Galvanized Steel Sheet C U Chann...

-

2019 Latest Design China Light Keel Corner Bead...

-

Discount wholesale Color Steel Sheet Roller Shu...

-

Newly Arrival Garage Door Machine Shutter Door ...

-

PriceList for Light Steel Keel Roll Forming Mac...

-

Quots for Double Layer Roll Forming Machine/met...