Best Price on Bending Sheet Machine - Hot-selling Double Layer Roofing Sheet Forming Machine – Haixing Industrial Detail:

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Hot-selling Double Layer Roofing Sheet Forming Machine, Influenced from the swift building marketplace of the quick food and beverage consumables all over the planet , We’re wanting forward to operating with partners/clients for making good results together.

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Corrugated Roof Sheet Making Machine, Roofing Sheet Bending Machine, Roofing Sheet Forming Machine, Our company mission is that providing high quality and beautiful solutions with reasonable price and strive to gain 100% good reputation from our clients. We believe Profession achieves excellence! We welcome you to cooperate with us and grow up together.

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

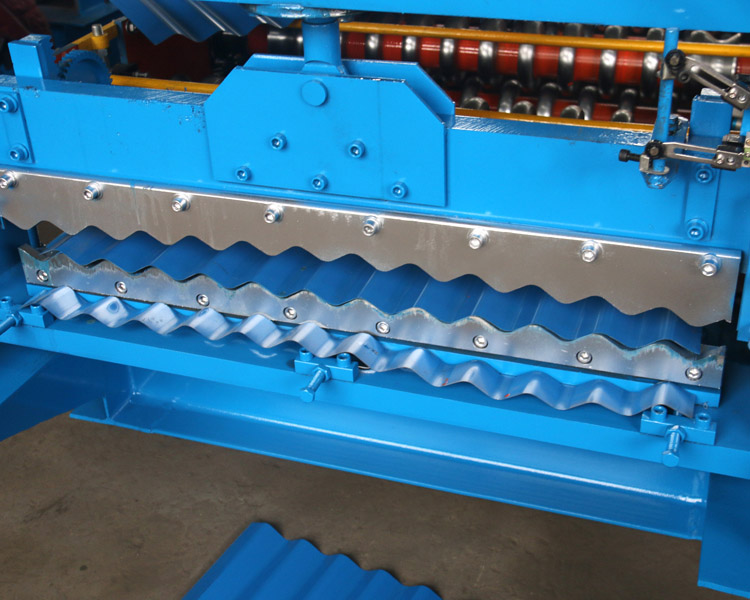

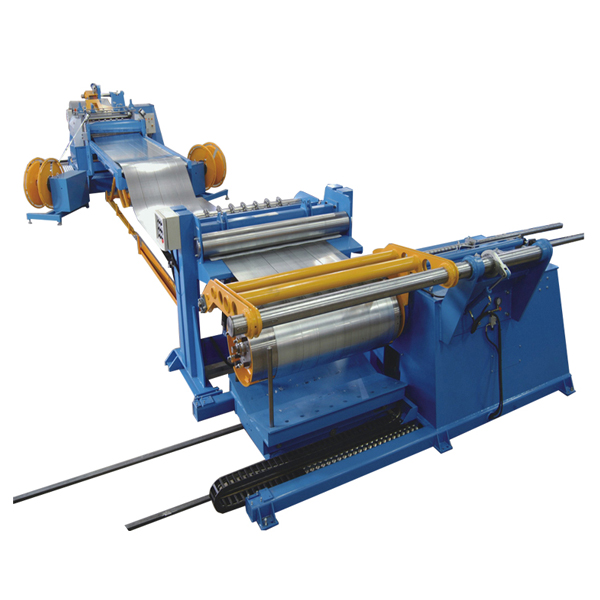

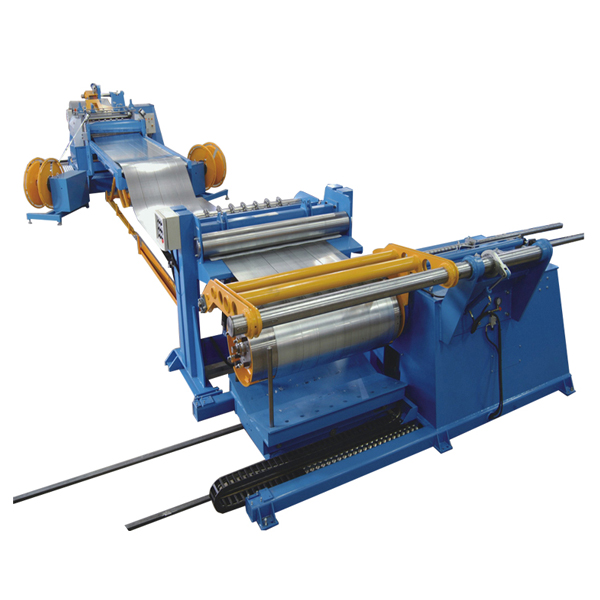

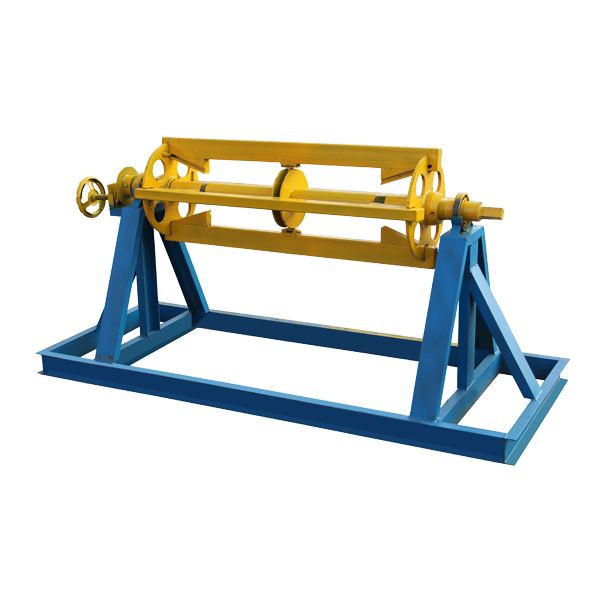

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

Product detail pictures:

Related Product Guide:

Top 10 Superyachts At The Fort Lauderdale International Boat Show | Floor Deck Macking Machine

NFPA-502 Fire Protection Case Histories: Elizabeth River Tunnel and the Hugh L. Carey Tunnel | Decoiler In Color Coating Line

Best Price on Bending Sheet Machine - Hot-selling Double Layer Roofing Sheet Forming Machine – Haixing Industrial, The product will supply to all over the world, such as: , , ,

-

China Gold Supplier for Portable Hydraulic Shea...

-

OEM manufacturer Steel Floor Decking Roll Formi...

-

Manufactur standard Steel Floor Decking Tile Ro...

-

OEM Factory for Poprtable Gutter Machine - C c...

-

2017 wholesale price Hand Operated Bending Mach...

-

Hot-selling Metal Gutter Making Machine - Manu...