Automatic roofing tile roll forming machine parameters

| Control system | Automatic PLC control system |

| Mainframe | 350/400H beams |

| Chain size | 1 inch/1.2inch according to machine demands |

| Roll station | Common 11rolls or 25rolls |

| Roller diameter | 70/75/80mm (depends on different design) |

| Roller material | 45# steel |

| Cutter material | Cr12MOV |

| Cr-plating size | 0.05mm |

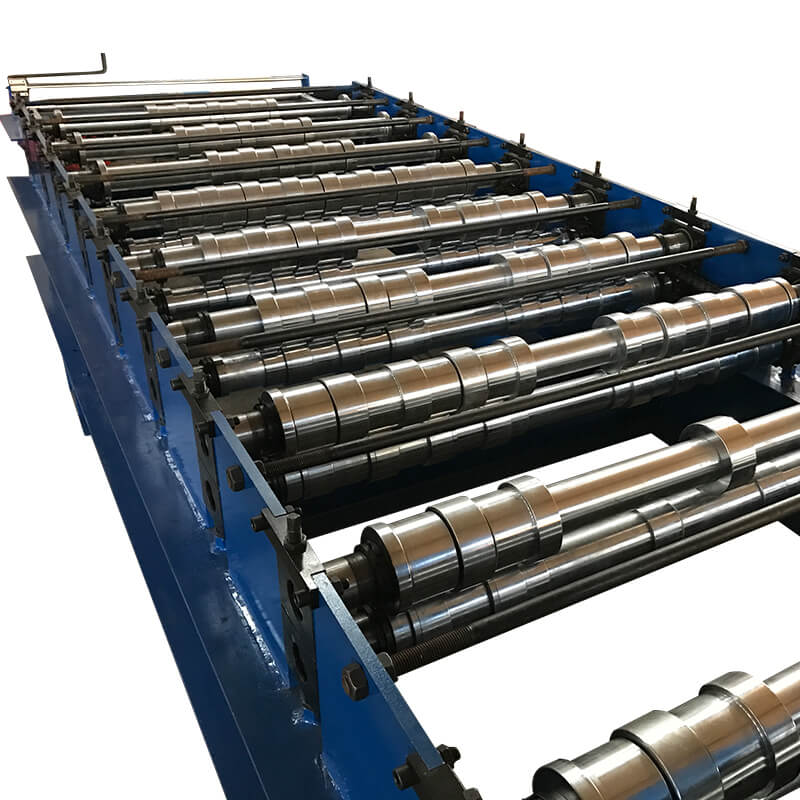

Automatic roofing tile roll forming machine picture display

Automatic roofing tile roll forming machine details

Detail display of the automatic roofing tile roll forming machine parts

01. Mainframe: GB H steel, hard texture.

02. Operator station: 360-degree rotation display.

03. Cutter: The main material is Cr12, which has high hardness.

04. Retaining pad: Prevent the nut from loosening.

05. Easy hanging: Prevent the machine from scratching during the movement.

06. Wheel: generally 45# steel, good hardness.

07. Travel switch: Limit the position or travel of the machine.

08. Rear hand knife: cut in advance to prevent waste.

09. Resin wheel: used to record the length of discharge and record data is more accurate.

10. Electric control cabinet: The main brands are Panasonic / Siemens / Schneider / Delta PLC.

About us

HAIXING INDUSTRY GROUP CO.,LTD, not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

First, We have professional technicians for loading: Guaranteed the goods load into containers without any damage.

Second, Transportation: Machines need one 40 feet container to hold(based on machine size).

Third, Please provide us the nearest port name, we will be ask shipping cost and arrange shipping for you based on your need.

1. Main machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton.