The finished product of Automatic Metal Frame Stud And Track Roll Forming Machine is widely used in the construction of various roof ceilings, industrial plants, villages, warehouses, supermarkets, hotels, exhibition, family construction, shopping malls shutter doors and etc. It has the advantage of beautiful, classical appearance and grace taste.

Automatic Metal Frame Stud And Track Roll Forming Machine Forming Device Technical Parameter

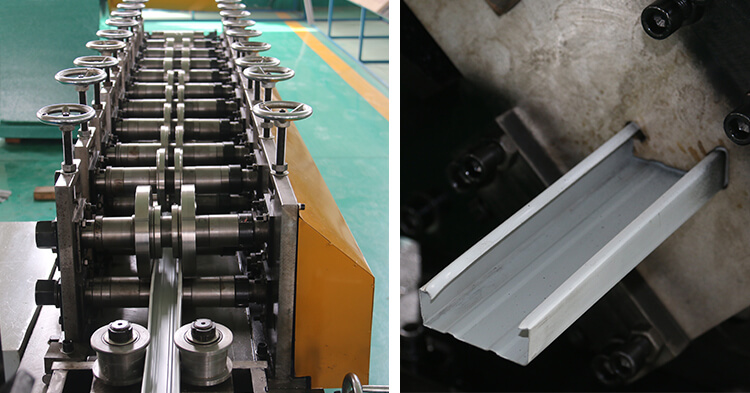

| Name | Specification |

| Rollers for forming | 16 Rows |

| Roller material | Cr12 |

| roller inner diameter | Φ40mm |

| roller outer diameter | minΦ90mm |

| heat treatment hardness | HRC58-62 |

| Symmetry | ≤0.05 |

| Motor power | 3kw |

| Transmission mode | chain drive + gear transmission |

| Side plate thickness | 25mm |

| Shaft material | 45# steel |

| Feeding positioning | Manual positioning, flexible adjustment at both ends |

| Control system | PLC programming controller, with the touch screen automatic control system |

| Stamp Die material | SKD11 |

| Stamp Die heat treatment hardness | HRC56-58 |

Other Parameters

Total power: 8.3kw

Forming Speed: 0~28m/min

Length after installation: 20m

Out table: Stainless operation table, bottom base is welded with an iron plate.

Automatic Metal Frame Stud And Track Roll Forming Machine details

Packaging details

Container packing of the line suitable for overseas shipping.

Free packaging for you;

Standard export packing: 20feet or 40 feet GP container; main false ceiling machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, the control box will be packed with carton box.

After Service

a. Two years guarantee for whole false ceiling machine.

b. 24 hours technical support by email or calling

c. If there is any problem found of the Ceiling T Bar Grids Forming Machine, we will repair it for free in one year.