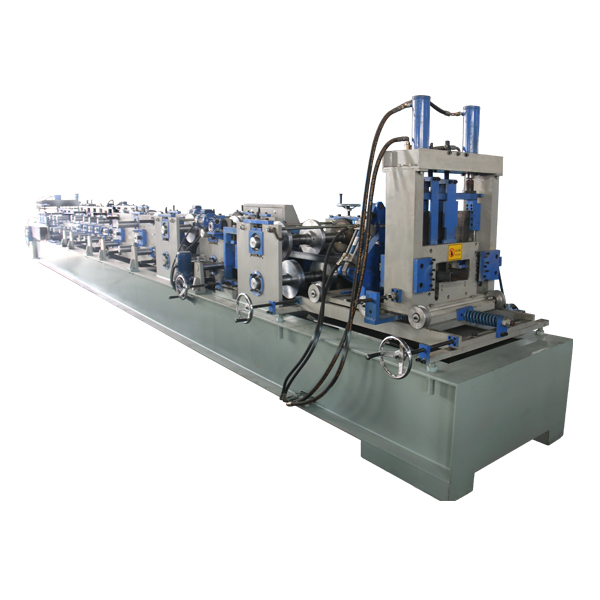

Automatic CZ interchange purlin machine process flow:

Manual decoiler– punching hole– roll forming machine– molding press– PLC control box– hydraulic system– post cut– output table.

|

Purlin roll forming machine

|

| 1 |

Suitable to process |

Steel plate |

| 2 |

Rollers |

18 rows(Before and after the leveling and contains no lead to send passes) |

| 3 |

Dimensions |

11*1.3*1.5m |

| 4 |

Power |

11.5kw+7.5kw |

| 5 |

Thickness of the plate |

1-3mm |

| 6 |

Productivity |

8-10m/min |

| 7 |

Middle plate thickness |

20mm |

| 8 |

Driving ways |

2.6-inch China wheels and link chain |

| 9 |

Diameter and material of the forming axis |

80mm |

| 10 |

Weight |

About 8.5T |

| 11 |

Voltage |

380V 50HZ3 phase |

| 12 |

Roll material |

GCr15(bearing steel)hard chrome plated after heat treatment |

| 13 |

Shaft material |

40Cr Modulation of heat treatment after polishing hard chromium plating |

| 14 |

On both sides of the wall material |

A3 steel |

| 15 |

Frame |

International H-beam |

| 16 |

Blade material |

Cr12Mov |

| 17 |

Forming wheel |

Bearing steel quenching |

The machine comprises the following parts:

Single-end feeding machine(max capacity 5T), Feeding leveling, Forming system, Straightening mechanism(one word original), At single + double holes, After forming shear system, Supporting material platform(6m)

Machine picture display

Terms:

1. Delivery: within 60 days after receiving the deposit

2. Package: export standard package for container

3. Payment: TT(30% by TT in advance, 70% by TT after inspect the machine before delivery)

Previous: C Shape Purlin Roll Forming Machine

Next: U Section Purlin Roll Forming Machine