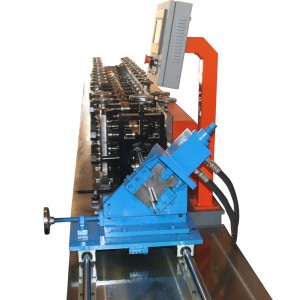

Automatic Ceiling Grid T Bar Sheet Metal Roll Forming Machines Forming Device Technical Parameter

| Name | Specification |

| Rollers for forming | 16 Rows |

| Roller material | Cr12 |

| roller inner diameter | Φ40mm |

| roller outer diameter | minΦ90mm |

| heat treatment hardness | HRC58-62 |

| Symmetry | ≤0.05 |

| Motor power | 3kw |

| Transmission mode | chain drive + gear transmission |

| Side plate thickness | 25mm |

| Shaft material | 45# steel |

| Feeding positioning | Manual positioning, flexible adjustment at both ends |

| Control system | PLC programming controller, with the touch screen automatic control system |

| Stamp Die material | SKD11 |

| Stamp Die heat treatment hardness | HRC56-58 |

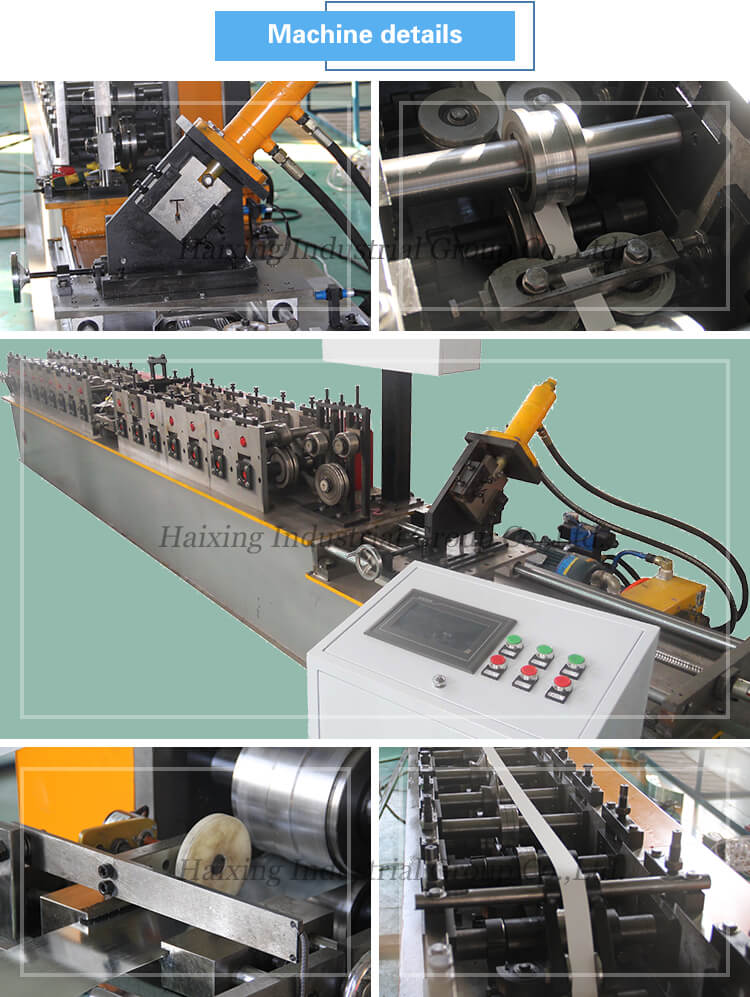

Machine details

Automatic Ceiling Grid T Bar Sheet Metal Roll Forming Machines‘ out table uses Stainless operation table, bottom base is welded with iron plate.

Packaging details

Container packing of the line suitable for overseas shipping.

Free packaging for you;

Standard export packing: 20feet or 40 feet GP container; main false ceiling machine naked and fastened with iron wire in the container, rollers were painted with oil and packed with plastic film, the control box will be packed with carton box.

FAQ

1)Q: Do you have after-sales support?

A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running.

2) Q: How do your machines compare with other big companies in this market?

A: We are up to date with the latest technology and improve our machines accordingly

3)Q: How does your factory do regarding quality control?

A: Quality is the priority. we always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it’s packed for shipment.

4) Q: Do you sell only standard machines?

A: No, most of our machines are built according to customers specifications, using top brand name components.