Auto Curved Roll Forming Machine For Roofing Details

| Main motor power | 5.5kw, 3 phase or as your request |

| Hydraulic motor power | 4kw |

| Hydraulic Pressure | 10-12MPa |

| Voltage | 380V /3phase/ 50 HZ (or as your requirement) |

| Control System | PLC Delta Inverter |

| Main Frame | 300mm/350mm H-Beam or 350mm |

| Backboard Thickness | 16mm |

| Chain Size | 1 Inch |

| Feeding Material | color steel coils |

| Feeding Thickness | 0.3-0.8mm |

| Feeding Width | 100-1200mm |

| Effective width | 840-1050mm |

| Productivity | 0-15/min |

| Roll Station | 13 roll steps(according to different design) |

| Roller Diameter | 70mm(depend on different design) |

| Roller material | 45# steel |

| Cutter material | Cr12 |

| Cr-Plating Size | 0.05mm |

| Overall Size | 6800*1400*1150mm |

| Total Weight | 5.8T |

Auto Curved Roll Forming Machine For Roofing Applications

The curved panels produced by Auto Curved Roll Forming Machine For Roofing are used for the door and wall.

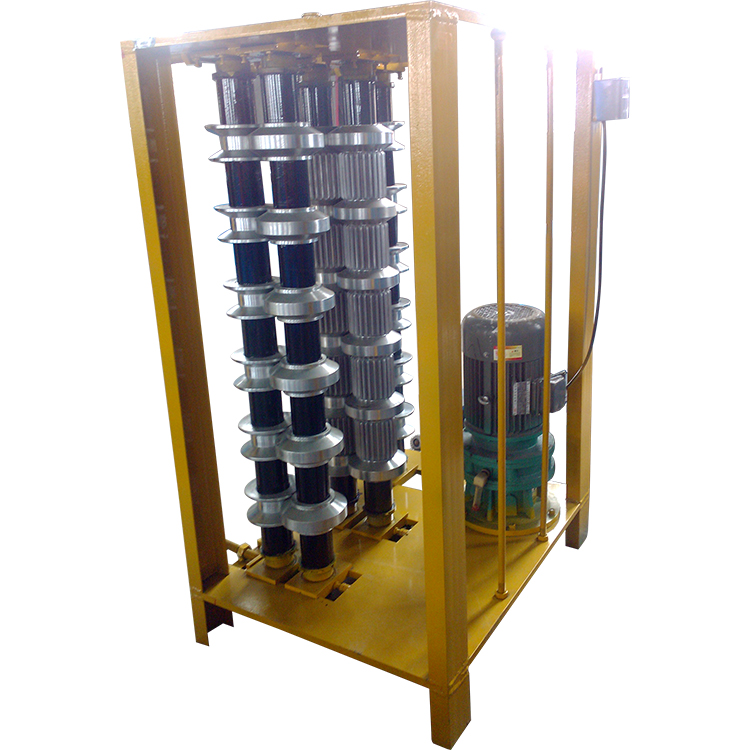

Machine Photos

Company Profile

Our products include roof roll forming machines, Leveling and shearing machines, decoilers, c&z purlin roll forming machines, slitting lines, Light steel keel roll forming machines and other associated equipment.

All products comply with international quality standards and are greatly appreciated in a variety of different markets throughout the world, such as Asia, Africa, Europe, South America, and Australia and so on.