|

Technical parameters:

|

|

1

|

Cutting & Hydraulic type

|

Double guide pillar

|

|

2

|

Hydraulic motor power

|

3kw or 4kw

|

|

3

|

Hydraulic Pressure

|

10-12MPa

|

|

4

|

Voltage

|

380V /3phase/ 50 HZ (or as your requirement)

|

|

5

|

Cutting drive

|

Decelerating motor + Chain drive gear all by

high-frequency

|

|

6

|

Control System

|

Panasonic /Siemens / Schneider / Delta PLC

|

|

7

|

Length measurement

|

Encoder

|

|

8

|

Main Frame

|

300mm/350mm H-Beam or 350mm

|

|

9

|

Backboard Thickness

|

17mm/200mm

|

|

10

|

Chain Size

|

1inch/2inch

|

|

11

|

Feeding Material

|

As your drawing or from our designer

|

|

12

|

Feeding Thickness

|

0.18mm-0.8mm

|

|

13

|

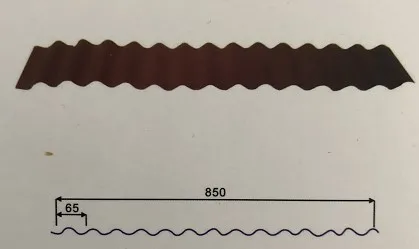

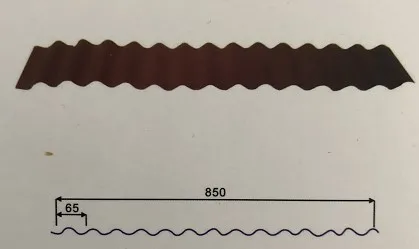

Effective width

|

As your drawing or from our designer

|

|

14

|

Productivity

|

10-15/min

|

|

15

|

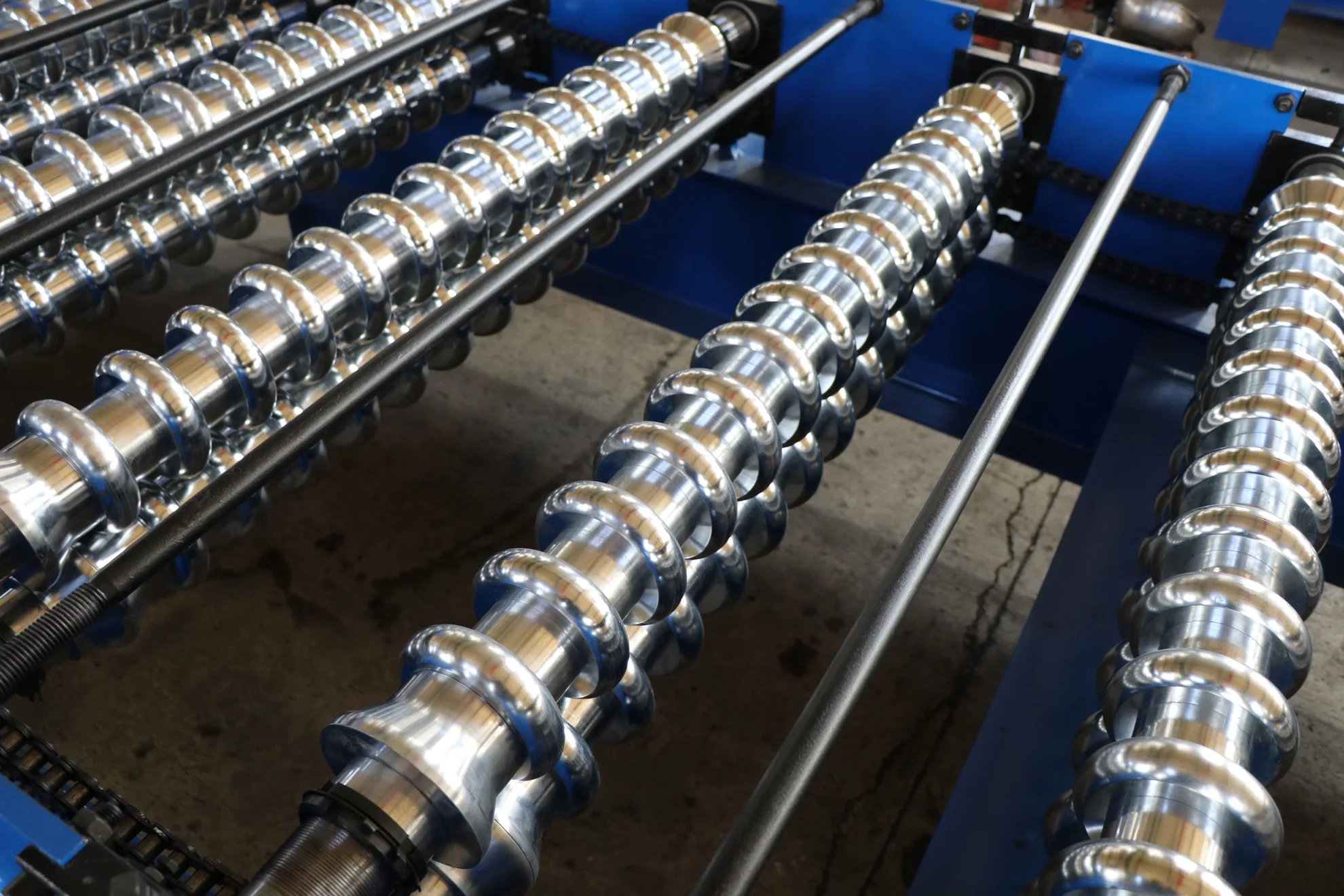

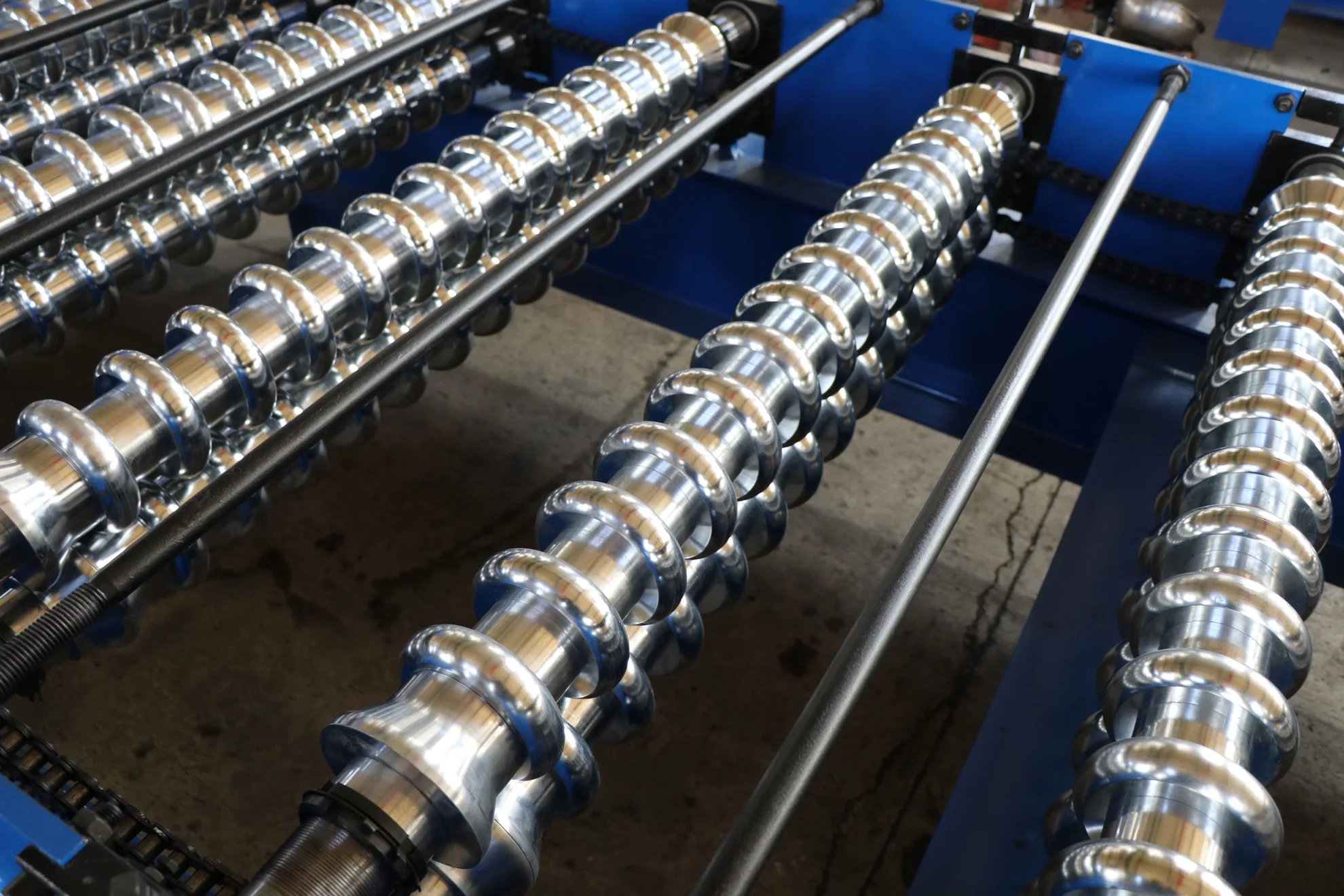

Roll Station

|

From11 rows (according to different design)

|

|

16

|

Roller Diameter

|

70mm/75mm (depend on different design)

|

|

17

|

Roller material

|

45# steel

|

|

18

|

Cutter material

|

Cr12 mould steel heat-treated hardness

of HRC 60-62 degrees

|

|

19

|

Total Weight

|

3t-12t

|

|

20

|

Package of machine

|

Waterproofing membrane, standard export packing

|

|

21

|

Components

|

Manual decoiler——————-1 set(5t)

Guiding Platform——————1 set

Coil Strip Leveler—————–1 set

Main Machine of Roll Forming—-1 set

Hydraulic Station—————- -1 set

Supporter Table——————-1 set

Coil Strip Leveler——————1 set

|

|

23

|

machine technical parameters can be changed, according to customer’s need.

|

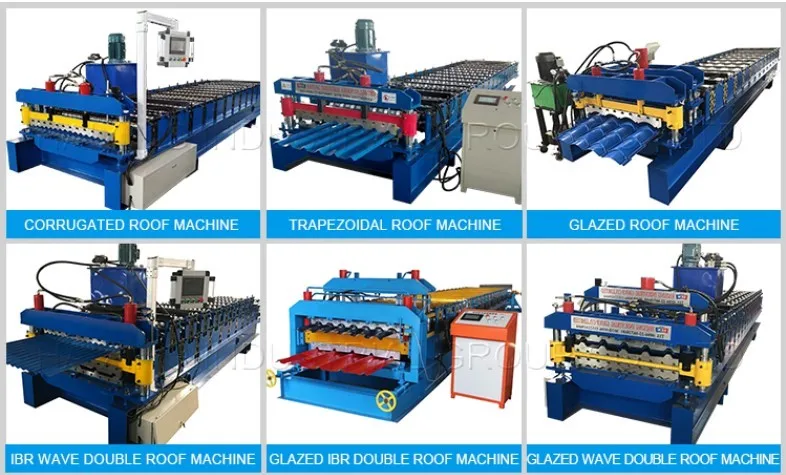

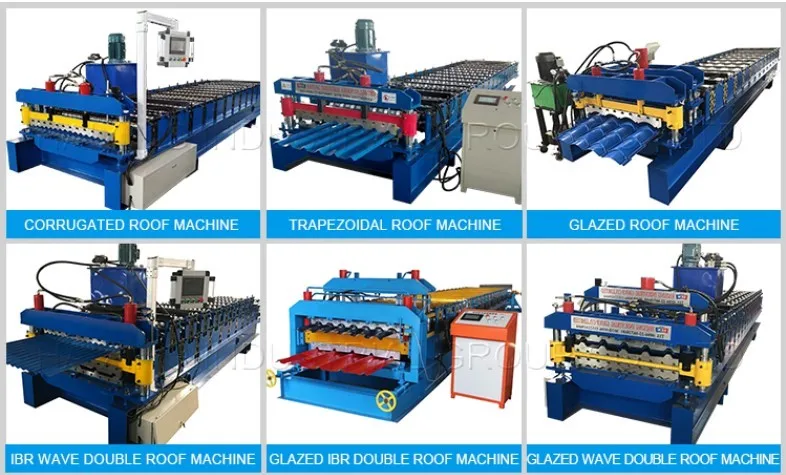

Detail show

Component parts show

Un set manual decoiler free:

PLC control:

Motor electric and hydraulic cylinder:

Consumables:

Related machine:

Our advantage:

Installation: With installation instructions, the line is connected, is very easy to operate, only need to insert the pin.

After service: Two years guarantee for machine; 24 hours technical support by email or calling; If there is any problem found of the machine, we will repair it for free within two years.

Easy to use: Our PLC is installed on the machine to reduce the space.

And the PLC can be rotated to check the sheet while controlling.

Our factory:

Previous: 10% discount 850 model corrugated metal roof sheet roll forming machine in stock

Next: Ibr galvanized steel roofing sheet roll forming machine