We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for 2019 wholesale price Color Steel Galvanized Metal Trapezoidal Roof Tile Sheet Roll Forming Machine, We warmly welcome all intrigued customers to speak to us for additional information and facts.

We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for Color Steel Galvanized Machine, Roof Sheet Roll Forming Machine, Trapezoidal Roof Machine, With the development and enlargement of mass clients abroad, now we’ve set up cooperative relationships with many major brands. We’ve got our own factory and also have many reliable and well-cooperated factories in the field. Adhering to the “quality first, customer first, We’re provideing high-quality, low-cost products and solutions and first-class service to customers. We sincerely hope to establish business relationship with customers from all over the world on the basis of quality, mutually benefit. We welcome OEM projects and designs.

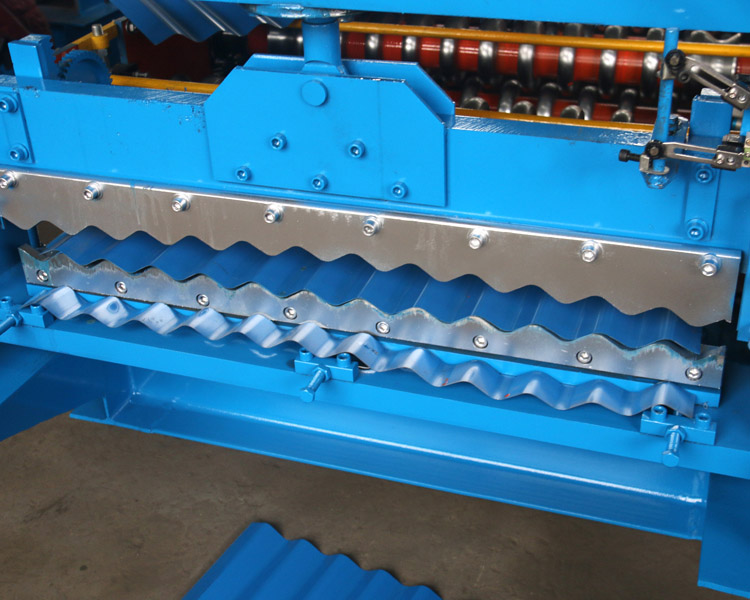

Parameters of corrugated automatic roof tile machine

| 1 | Main motor power | 4kW, 3-phase or as your requests |

| 2 | Hydraulic motor power | 3kW |

| 3 | Hydraulic pressure | 10-12MPa |

| 4 | Voltage | 380V/3-phase/50Hz (or as your requirements) |

| 5 | Control system | PLC delta inverter |

| 6 | Mainframe | 300/350mm H-beam or 350mm |

| 7 | Backboard thickness | 16mm |

| 8 | Chain size | 1 Inch |

| 9 | Feeding material | color steel coils |

| 10 | Feeding thickness | 0.3-0.8mm |

| 11 | Feeding width | 1000mm |

| 12 | Effective width | 850mm |

| 13 | Productivity | 0-15/min |

| 14 | Roll station | 13 roll steps (according to different design) |

| 15 | Roller diameter | 70mm (depends on different design) |

| 16 | Roller material | 45# steel |

| 17 | Cutter material | Cr12 |

| 18 | Cr-plating size | 0.05mm |

| 19 | Overall size | 6800*1400*1150mm |

| 20 | Total weight | 4.8 tons |

The above are some of the parameters, more detailed parameters can be obtained by contacting us, some of which can be customized according to customer needs.

Detail of machine:

Packaging Details:

1. Machine is covered by plastic film.

2. PLC control box, spare parts and other small parts are packed by wooden carton box.

-

Fast delivery Steel Light Gauge Roll Forming Ma...

-

Supply OEM/ODM Hot Sale Galvanized Sheet Used S...

-

Manufactur standard s Making Building Material ...

-

High Performance Hot Steel And Iron Roller Shut...

-

Discount wholesale Color Steel Sheet Roller Shu...

-

China Wholesale China Hot Sale Aluminum Metal R...